Whether you're cutting simple parts or tackling high-mix, high-precision work, we have the machines to move your shop forward. From lathes and milling machines, to automation and multitasking solutions, our inventory covers every step of modern manufacturing. Every machine comes with the full backing of Morris, delivering expert service, responsive support, and a commitment to long-term success.

Turning Machines

Turning Machines

Milling & Machining Centers

Multitasking

Large Part Machining

Automation & Support

Accessories

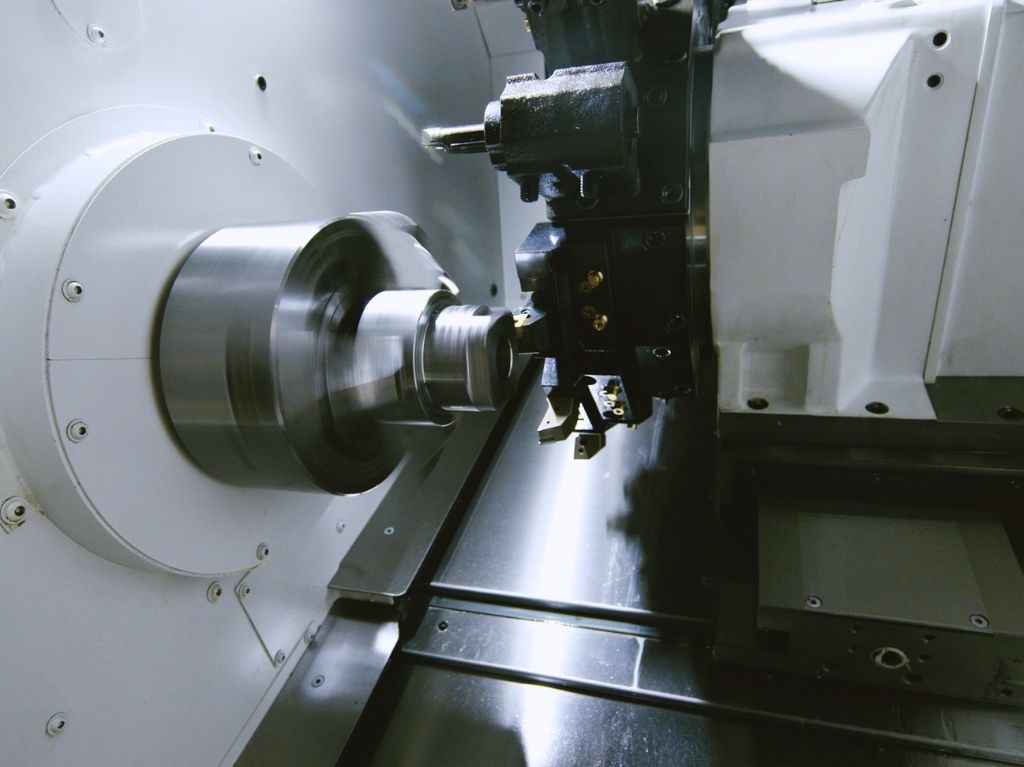

Horizontal Lathes

Designed for turning long, cylindrical workpieces, horizontal lathes provide stable support to ensure consistent diameters and smooth surface finishes. Ideal for production runs of shafts, rods, and pipes, these machines deliver precise, repeatable results. With robust construction and intuitive controls, horizontal lathes help shops maintain efficiency and quality across every turning operation.

Vertical Lathes

Vertical lathes support heavy, wide parts with ease thanks to their upright design. They’re perfect for brake rotors, valves, and other components that benefit from gravity-aided stability. These machines help reduce cycle times and increase metal removal rates, delivering productivity where weight and balance matter most.

*Famar is only available in AL, AR, GA, MS, NC, SC, TN, and VA

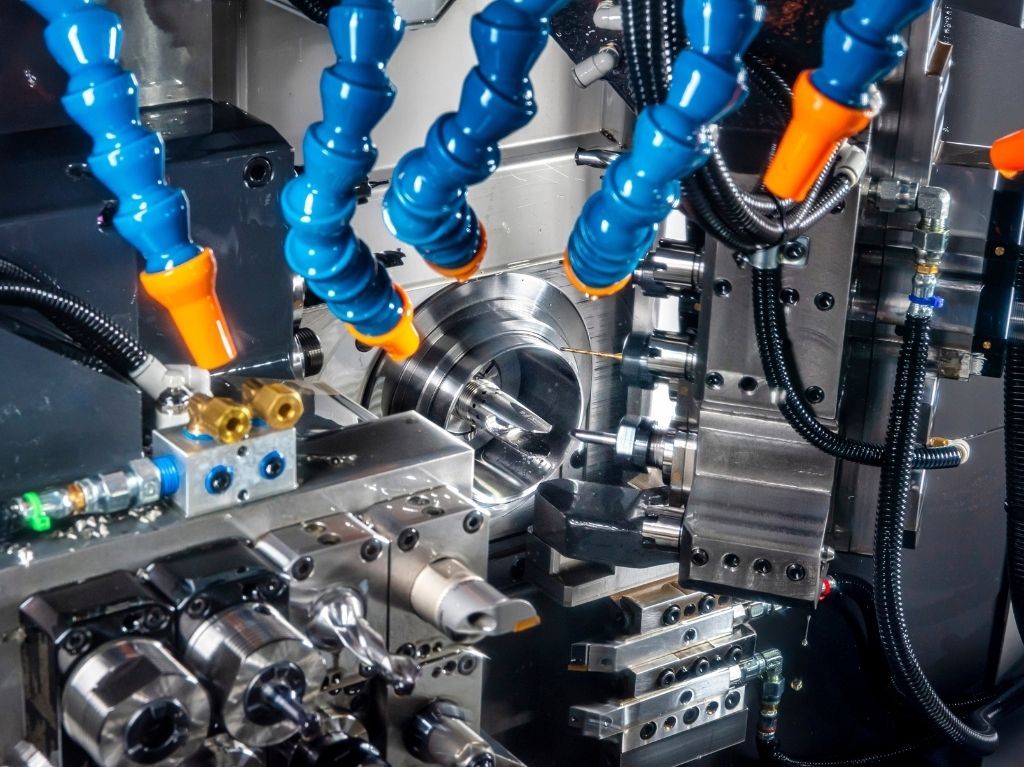

Swiss

Swiss machines specialize in high-precision, small-diameter parts often needed in medical, electronics, and aerospace applications. With their sliding headstock design, they maintain accuracy over long runs. Tsugami’s Swiss lineup offers unmatched performance for intricate, high-volume parts where every thousandth of an inch counts.

Turning Centers

Turning centers are designed to efficiently produce round or cylindrical components with consistent precision. These machines often incorporate advanced features such as live tooling, multiple spindles, and multi-axis capabilities to support complex part geometries and reduce secondary operations.

*Famar is only available in AL, AR, GA, MS, NC, SC, TN, and VA

Milling & Machining Centers

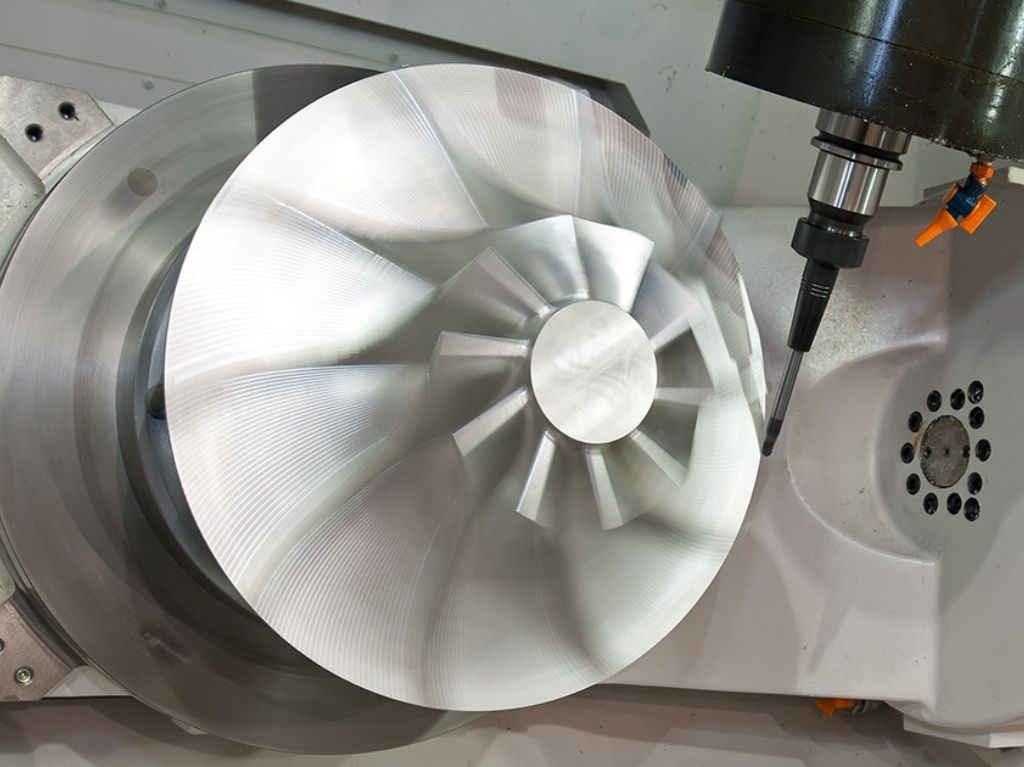

5-Axis

5-axis machining provides five degrees of motion to produce intricate geometries in a single setup. By cutting multi-sided parts without repositioning, it delivers superior surface finishes and tight tolerance control. Essential for aerospace and medical applications, 5-axis machining slashes cycle times and boosts repeatability in complex, high-precision production.

*Fausto Marinello is only available in AL, AR, GA, MS, NC, SC, TN, and VA

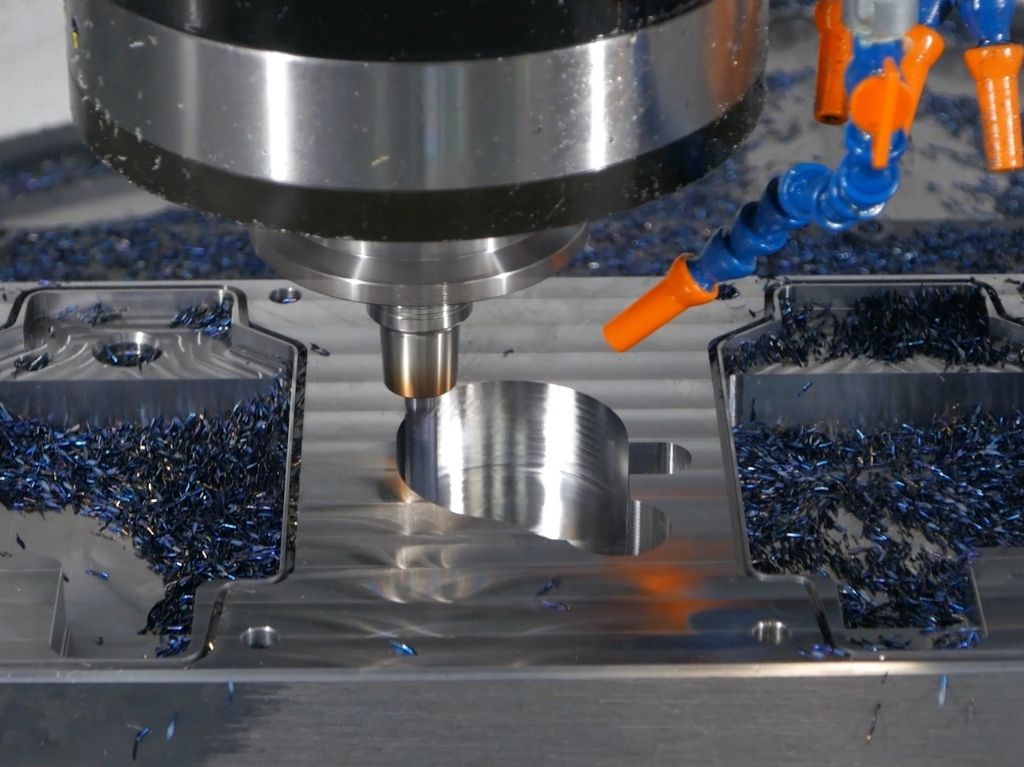

Milling

Milling machines deliver precise material removal using rotary cutting tools. Available in vertical, horizontal, and multi-axis formats, they support drilling, slotting, and surface finishing across diverse materials. From one-off prototypes to high-volume runs, these machines ensure consistent accuracy and efficient cycle times.

*Fausto Marinello is only available in AL, AR, GA, MS, NC, SC, TN, and VA

Machining Centers

Machining centers are built to handle milling, drilling, tapping, and more—all in one setup. Available in 3, 4, or 5-axis formats, machining centers bring versatility and speed to any shop floor. Whether vertical, horizontal, or inverted, these systems shorten lead times and increase throughput.

*Fausto Marinello is only available in AL, AR, GA, MS, NC, SC, TN, and VA

Horizontal Machining Centers

Horizontal machining centers (HMCs) are built to tackle heavy-duty materials and complex geometries with superior chip flow and tool life. Their layout minimizes downtime and increases productivity, especially on multi-face parts. HMCs make it easier to handle larger components with better accessibility and fewer setups, making it ideal for production-focused environments.

*Fausto Marinello is only available in AL, AR, GA, MS, NC, SC, TN, and VA

Inverted Machining Centers

Inverted machining centers optimize manufacturing with their downward-facing spindle that enhances automation, improves chip and coolant management, and offers access to complex part contours. These compact machines are ideal for industries like automotive and aerospace.

Morris features inverted machining centers from FAMAR, designed to meet the demands of high-volume and precision-focused manufacturing.

*Famar is only available in AL, AR, GA, MS, NC, SC, TN, and VA

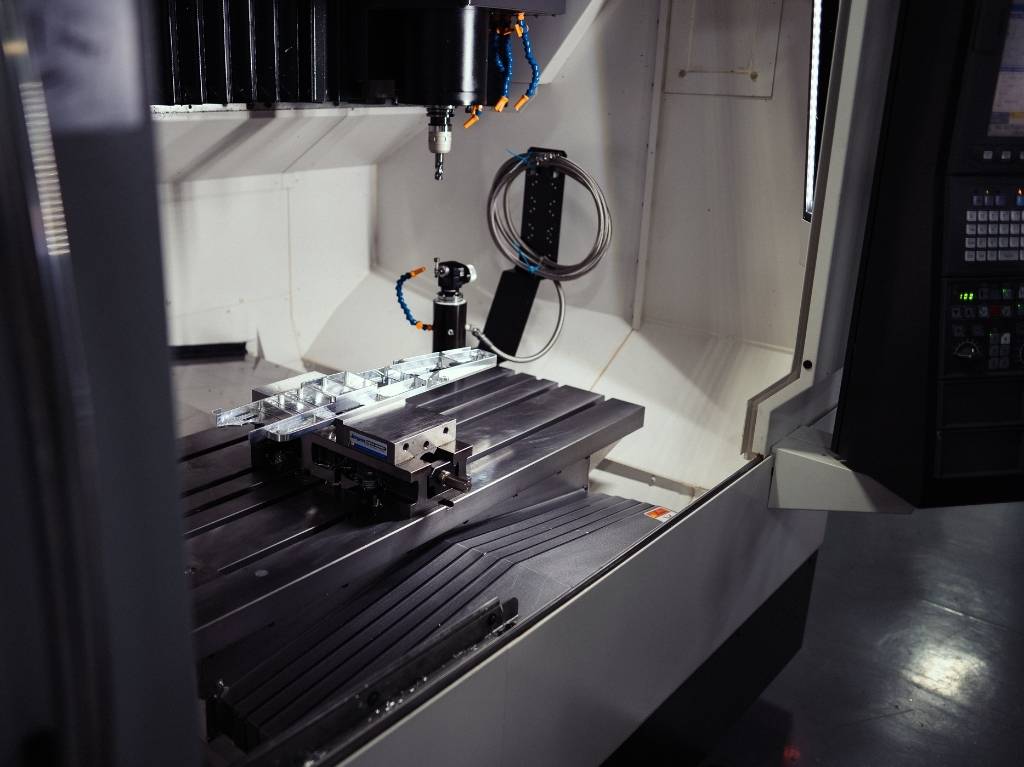

Vertical Machining Centers

Vertical Machining Centers (VMCs) deliver high-speed, multi-axis capability for efficiently producing parts with complex geometries and tight tolerances. By consolidating multiple operations into a single setup, VMCs reduce cycle times and improve overall part accuracy. These machines are an ideal choice for shops aiming to elevate productivity, minimize scrap, and ensure consistent quality across a variety of applications.

Multitasking

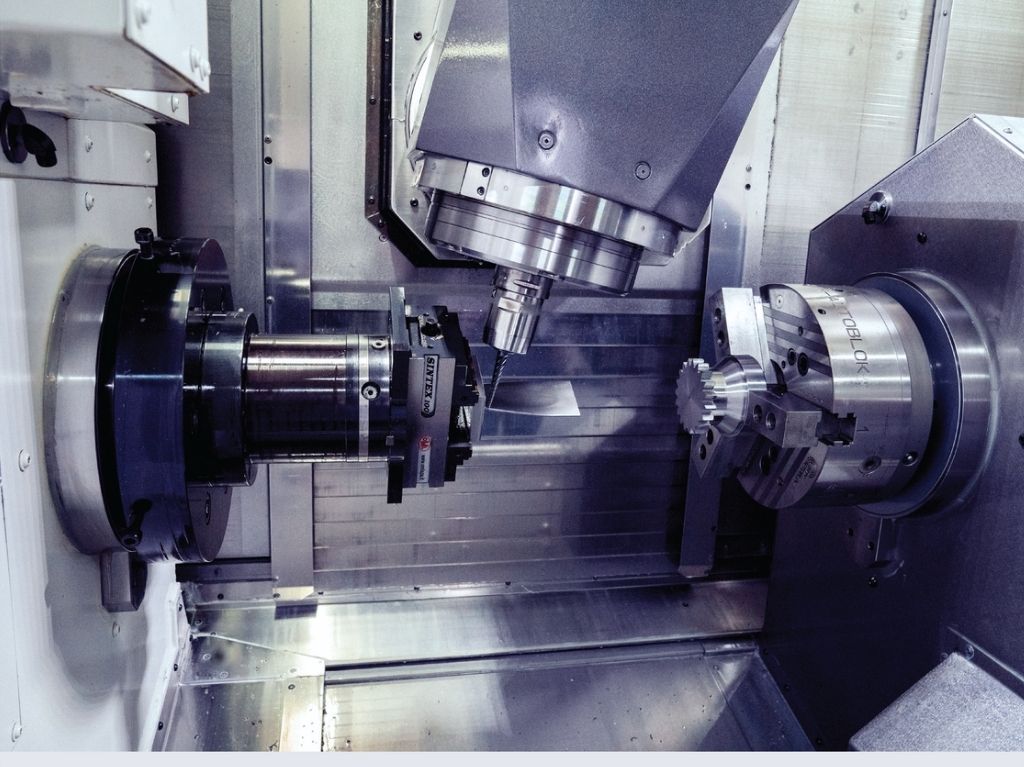

Multitasking & Multifunction

Multitasking machines combine turning and milling capabilities into a single platform, allowing complex parts to be completed in one setup.

Multifunction machines go beyond traditional cutting operations by integrating advanced capabilities such as grinding, gear cutting, or in-process measurement alongside turning and milling.

*Famar and Fausto Marinello are only available in AL, AR, GA, MS, NC, SC, TN, and VA

Large Part Machining

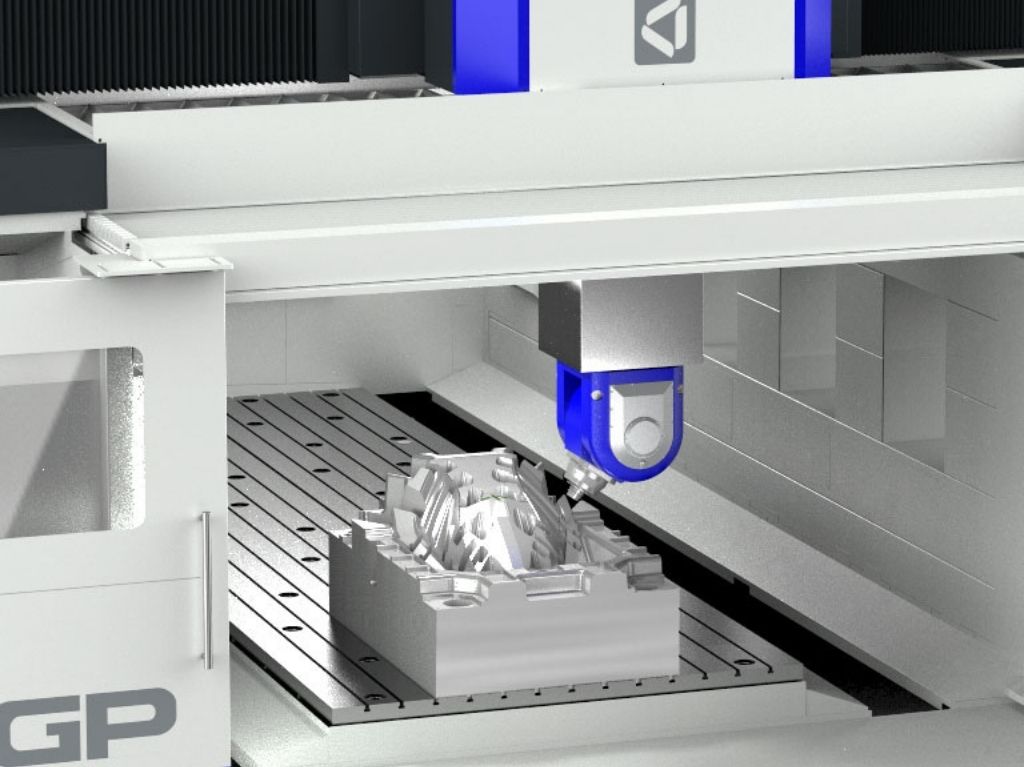

Double Columns

Double column machines offer the rigidity and spacious work envelopes needed for handling large-scale, heavy-duty parts. Perfect for mold-making and structural components, they bring unmatched accuracy to applications where stability and size are non-negotiable. Investing in a double column machine expands your capability to take on big, complex work without compromising precision.

High Rail Gantry

High rail gantry machines are built for oversized, heavy workpieces and multi-process operations. Their elevated structure improves chip and coolant evacuation while maintaining precision and operator safety. These Soraluce machines excel in mold making, aerospace, and composite machining.

Automation & Support

Automation

Automation systems streamline production and fill labor gaps by automating repetitive tasks. They’re ideal for shops looking to scale operations without increasing headcount. From robotic loaders to full turnkey solutions, automation helps reduce cycle times, increase output, and improve consistency.

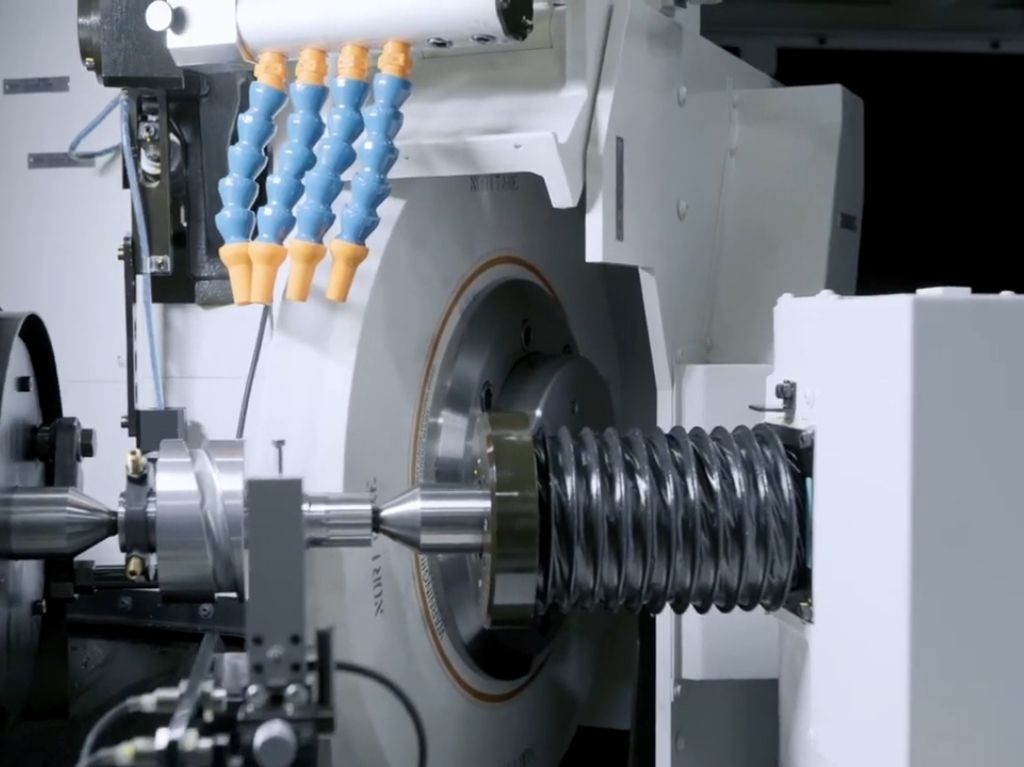

Grinders

Grinders are essential for achieving exact tolerances and polished finishes on critical parts. Whether you’re doing I.D., O.D., or surface grinding, these machines ensure repeatable quality in demanding applications. With options from semi-automatic to fully CNC, grinders provide the finishing precision your shop needs to meet spec requirements.

*Morris distributes Chevalier grinders in ME, VT, NH, CT, RI, NY, NJ, Western PA, WV, GA, AL, MS, and AR

Laser Marking Systems

Laser marking systems deliver permanent, high-contrast part markings without the mess of inks or etching chemicals. They’re great for serial numbers, barcodes, and branding. Morris offers user-friendly laser markers from TRUMPF* that handle batch-to-one production needs with safety and quality at the forefront.

*TRUMPF is only available in CT, MA, ME, Northern NJ, NH, NY, RI, VT, Western NY, Western PA, and WV

Manual Machines

Manual machines remain a vital part of every well-rounded shop. They’re ideal for quick one-offs, reworks, training, and repair work. When CNC isn’t necessary, manual machines offer agility and simplicity. Morris supports shops with a broad line of manual mills, lathes, and grinders for hands-on tasks that still matter.

For tooling, replacement parts, and maintenance support, Morris Plus is your go-to resource for keeping manual machines productive and reliable.

MACHINE TOOL ACCESSORIES

Coolant Systems

Coolant systems keep your tools and parts cool during cutting, improving tool life and surface finish. MP Systems designs and manufactures high-pressure systems that remove chips efficiently and reduce heat build-up. A good coolant system protects your investment and ensures smoother, faster machining across the board.

Machine Air Intake Filters

Machine air intake filters trap dust and debris before they enter your machine’s ventilation. Velum’s high-efficiency design maintains airflow while capturing contaminants. Reliable intake filtration protects internal components, reduces downtime, and extends equipment life.

Machine Vision & Monitoring

Spinning windows from Rotoclear and machine vision systems from UYAR VisionLine give you real-time visual access to your machining process. These tools help improve accuracy, safety, and uptime. Machine monitoring solutions help identify inefficiencies before they become problems, keeping your shop running smarter.

Mist Collectors

Mist collectors improve air quality by capturing coolant and oil aerosols during machining. The ExoMist HPMC line exceed OSHA and NIOSH standards, creating a safer, cleaner work environment. They’re a smart addition to any shop focused on health, cleanliness, and machine longevity.

Parts Cleaning & Vacuum Degreasers

MiJET offers eco-friendly, pneumatically operated parts cleaning units that reduce coolant usage and maintain a pristine work environment. ITF vacuum degreasers deliver hermetic cleaning for intricate components, removing oils and contaminants from blind holes and cavities. These solutions ensure thorough part cleanliness, extend tool life, and minimize maintenance downtime.

Our Technology Partners

TEL 860-687-3300

FAX 860-687-3476

FOLLOW US

© 2026 Morris. All Rights Reserved.

Privacy Policy | Site Map