Scalable Automation for Lights-Out Manufacturing

Okuma Flexible Manufacturing Systems (FMS)

Okuma’s FMS solutions deliver scalable, high-volume production with automated pallet handling and lights-out capability. These systems integrate with machining centers to reduce idle time and optimize throughput. Okuma offers flexible FMS options from EROWA, Fastems, and Daifuku to suit different shop sizes, workflows, and production goals.

Famar Automated Turning Centers

Famar’s inverted vertical lathes, also known as vertical pick-up turning machines, are purpose built for high-volume machining of complex parts. Each turning center features built-in automation and supports multiple operations in a single clamping for fully unattended, efficient production.

*Famar is only available in AL, AR, GA, MS, NC, SC, TN, and VA

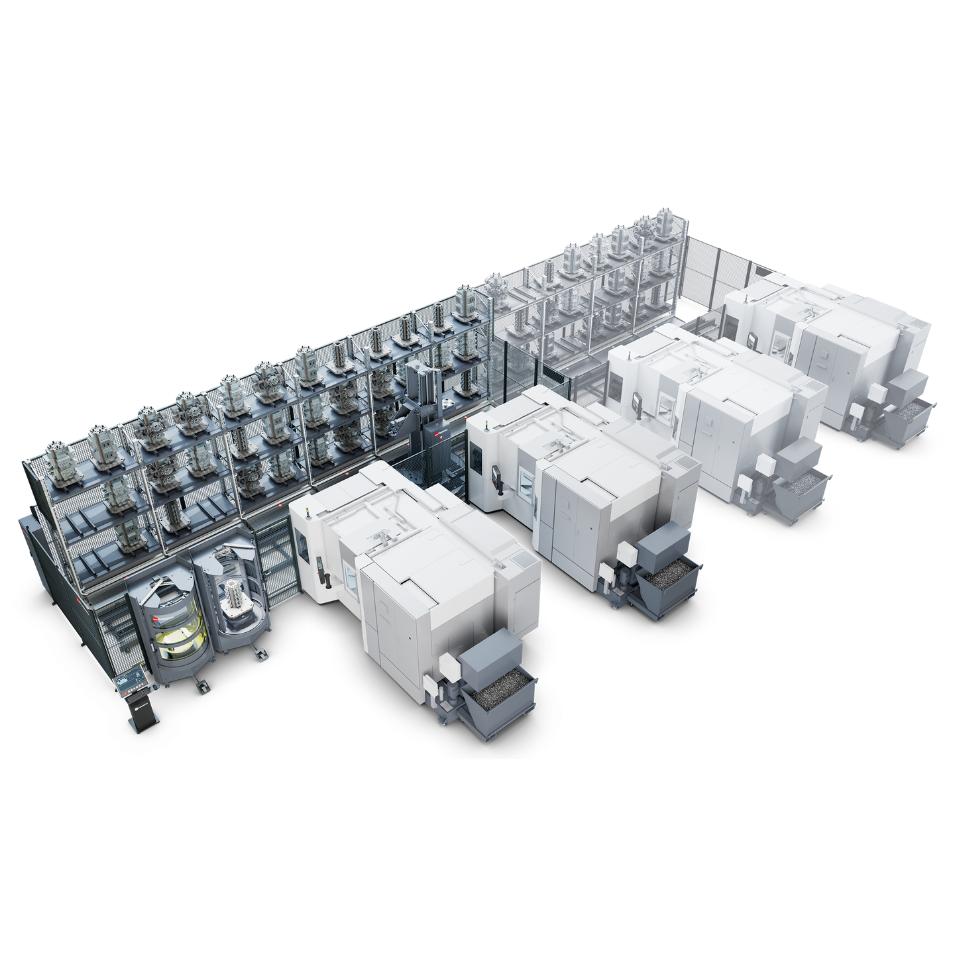

Okuma FMS – Daifuku Flexible Manufacturing Systems

The Daifuku FMS is a pallet-based automation system designed to run high-mix, variable-volume production across multiple Okuma machining centers.

With a compact footprint and a modular layout, the system can be configured to match your space and production needs. Inline or transverse pallet arrangements give it the flexibility to fit tight shop floors.

Fully integrated with Okuma’s THINC-OSP controls, the FMS uses a centralized pallet pool controller to automate scheduling and job routing without operator intervention.

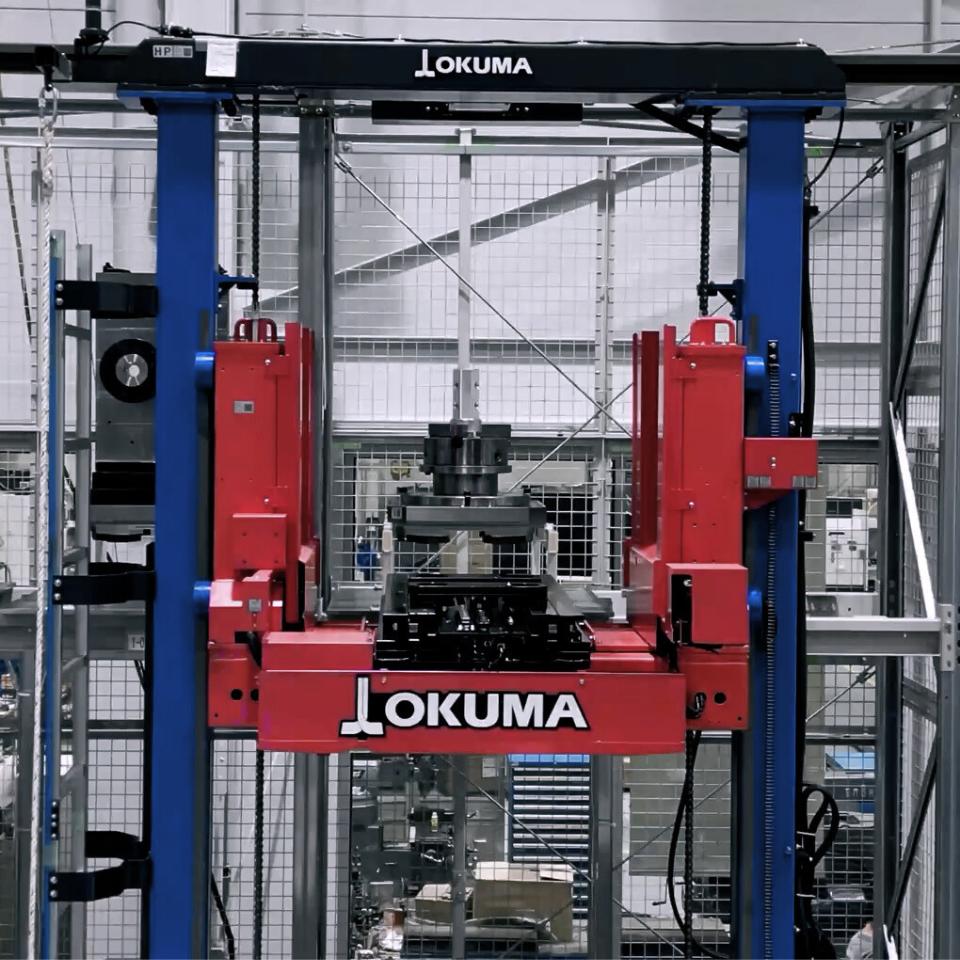

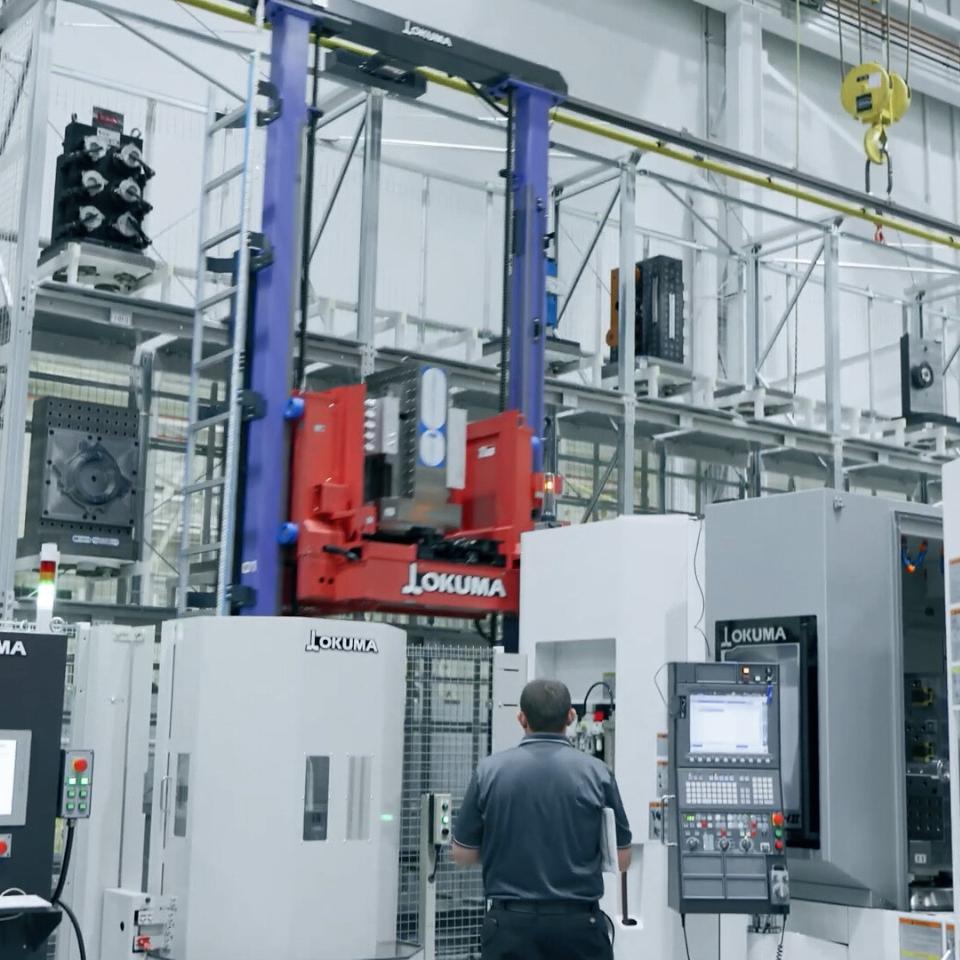

Okuma FMS – EROWA Robot Dynamic 150L

The Robot Dynamic 150L is a modular automation system designed to load and unload workpieces up to 331 lbs (150 kg). It integrates seamlessly with up to 12 machines, including Okuma machining centers, and supports batch sizes as small as one.

With a compact footprint and scalable rail system up to 98 feet (30 meters), the 150L is ideal for lights-out, high-mix production. Its rack magazine configurations, ergonomic loading stations, and RFID part tracking make it an efficient and user-friendly automation solution.

The system runs on EROWA’s JMS® 4.0 software, which keeps production flowing with live job status, tool tracking, and automatic job prioritization even across night and weekend shifts.

Okuma FMS – Fastems Flexible Pallet System

The FPS is a modular pallet automation system built for 4- and 5-axis milling or mill-turn Okuma machines. It fits shop floors with tight footprints thanks to its 360-degree layout.

Available for pallet sizes from 11.8 to 24.8 inches, the FPS be expanded or reconfigured to match changing production needs.

The system is powered by Fastems’ MMS software, which gives operators a real-time view of production and automatically schedules the next job to keep output on track.

FAMAR ERGO — Multi-Tasking Turning Center

FAMAR ERGO vertical lathes offer stand-alone or production turning solutions for all types of machining operations, from turning and drilling to milling, hobbling and grinding in one machine.

The ERGO is the ideal solution for machining complex parts at the highest volumes.

ERGO Product Range:

ERGO 200, ERGO 215, ERGO 260, ERGO 315, ERGO 400, ERGO 415, ERGO 500, ERGO 630, ERGO 815, ERGO 1250

*Famar is only available in AL, AR, GA, MS, NC, SC, TN, and VA

FAMAR TANDEM — Twin Spindle Turning Center

FAMAR TANDEM twin spindle, twin turret multi-tasking lathes maximize productivity while minimizing footprint. Two independent pallet conveyors feed the work area and loading system, enabling output to be doubled.

TANDEM Product Range:

TANDEM 200, TANDEM 215, TANDEM 260, TANDEM 315, TANDEM 400, TANDEM 415, TANDEM 500, TANDEM 630

*Famar is only available in AL, AR, GA, MS, NC, SC, TN, and VA

FAMAR PRONTO — Inverted Vertical Lathe

Single inverted-vertical spindle multitasking turning center with automation already built in. Ideal for both small and big batches and for all types of machining operations, The PRONTO strikes the right balance between flexibility and costs savings.

PRONTO Product Range:

*Famar is only available in AL, AR, GA, MS, NC, SC, TN, and VA

FAMAR SUB — High Speed Vertical Lathe

FAMAR SUB is a line of high speed inverted vertical lathes integrated with automation technology that loads and unloads parts in three seconds. The SUB model features a single work areas, while the BISUB offers two work areas.

SUB Product Range:

*Famar is only available in AL, AR, GA, MS, NC, SC, TN, and VA

FAMAR MAXER — Multiprocess Machining Center

FAMAR MAXER range replaces the traditional use of a CNC lathe + Milling Machine + Gantry Loader,” thus reducing investment costs and saving on space with multiple machining operations performing in a single clamping.

The FAMAR MAXER 400 vertical lathe is a versatile solution for turning mechanical parts of any shape and material up to 13 inches.

MAXER Product Range:

*Famar is only available in AL, AR, GA, MS, NC, SC, TN, and VA

Ready to Automate Your Operations?

Morris Automation can help you find the right setup to streamline your workflow. Fill out the form and our team will be in touch shortly.

TEL 860-687-3300

FAX 860-687-3476

FOLLOW US