How Preventative Maintenance Can Benefit Your Shop

- Avoid costly downtime.

- Improved reliability increases ROI.

- Ensures Warranty terms are validated.

- Extends the life of your machine.

- Part replacement can be monitored and budgeted.

- Reduce scrap from wear related changes to accuracy and alignment.

- Records of maintenance add value if the machine is sold.

Total Productive Maintenance Program

Our Total Productive Maintenance program is one of the most intensive and thorough in the industry. After completion of the maintenance session, we will present a report with our findings, along with any suggestions we may have to improve performance. Our intent is not only to provide regular yearly maintenance but to provide you with the highest degree of accuracy, repeatability, and production dependability that your equipment can provide.

Our TPM program involves:

Machining Centers

- All critical parallel and perpendicular measurements are checked.

- Spindle runout, load and temperature are checked before and after the spindle has been run up to max rpms for 30 minutes.

- Pull force retention is checked.

- The headstock areas are cleaned.

- Spindle and encoder belts are checked for wear and correct tension.

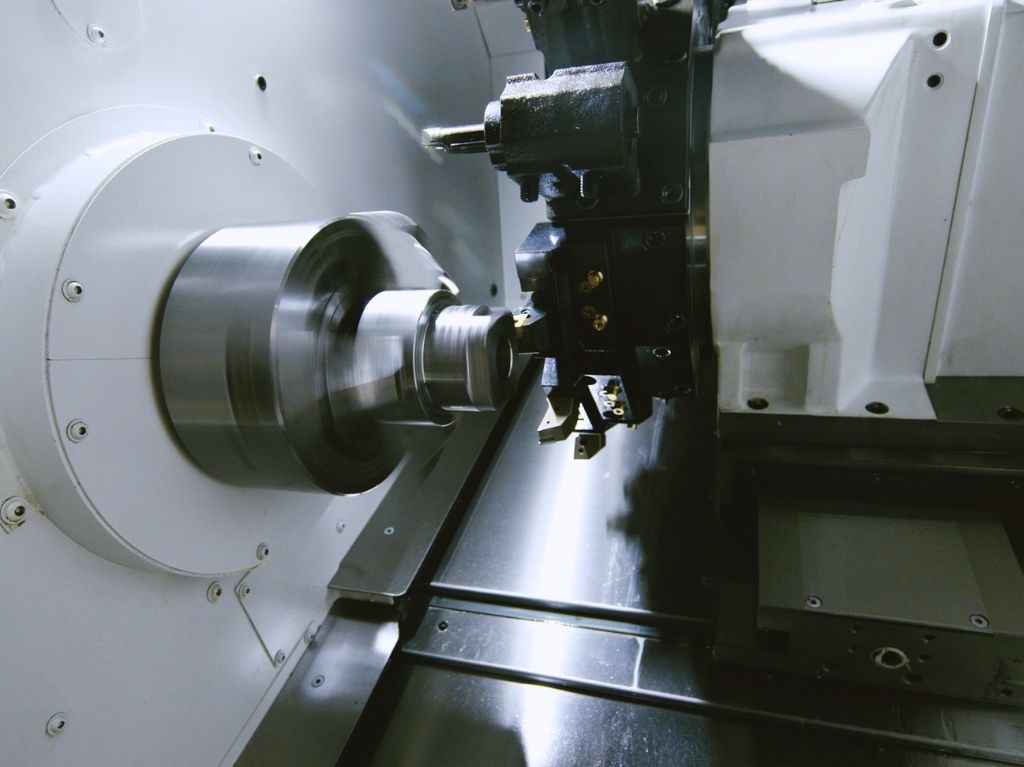

Lathes

- Turret

- Headstock

- Tailstock alignments

- Spindle runout

- Actuator runout

What We Cover

Fluids & Filters

- All oils and disposable filters are changed, and tanks are cleaned inside and out.

- Hydraulic, lubrication, air, and coolant line assemblies are checked for leaks.

- The lubrication system is checked to assure proper lube to the ball screws, ways, and linear guides.

- Spindle cooling units and gearbox lubrication systems are checked for proper operation.

Cooling & Airflow

- Motor cooling ribs and fans are cleaned.

- All fans are cleaned and checked for correct operation.

- Motor fans are cleaned, and brushes (where applicable) are checked.

- Heat exchangers, fans, and filters are cleaned.

- Drive units are removed from the electrical cabinet and heat exchangers and fans are cleaned.

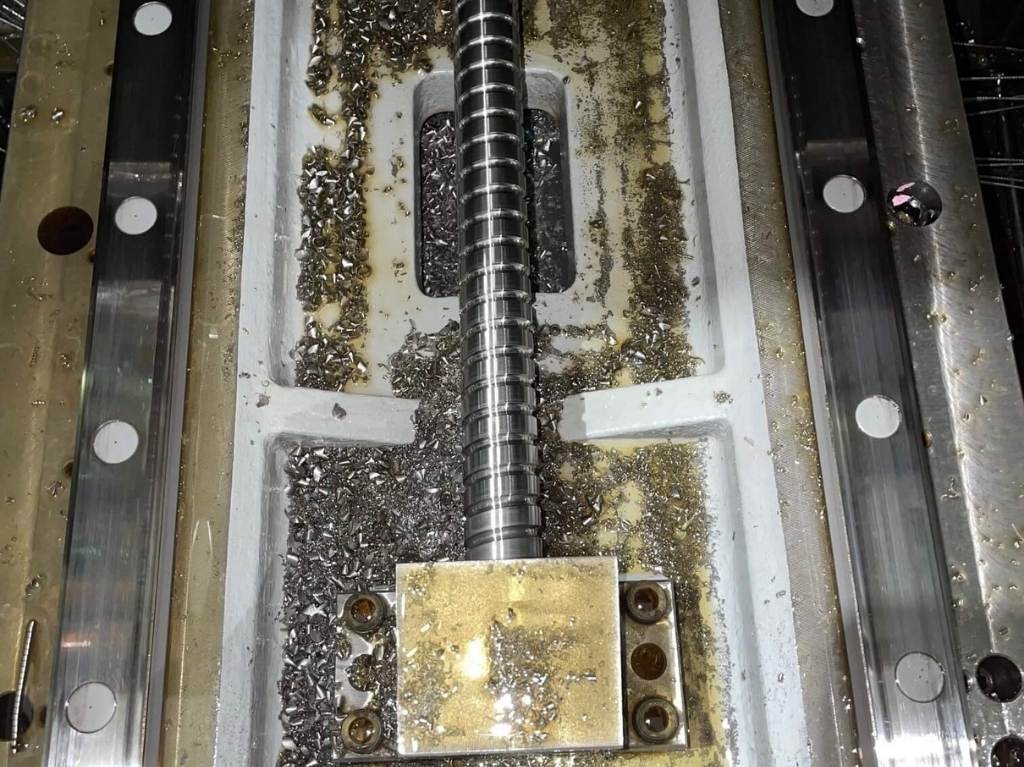

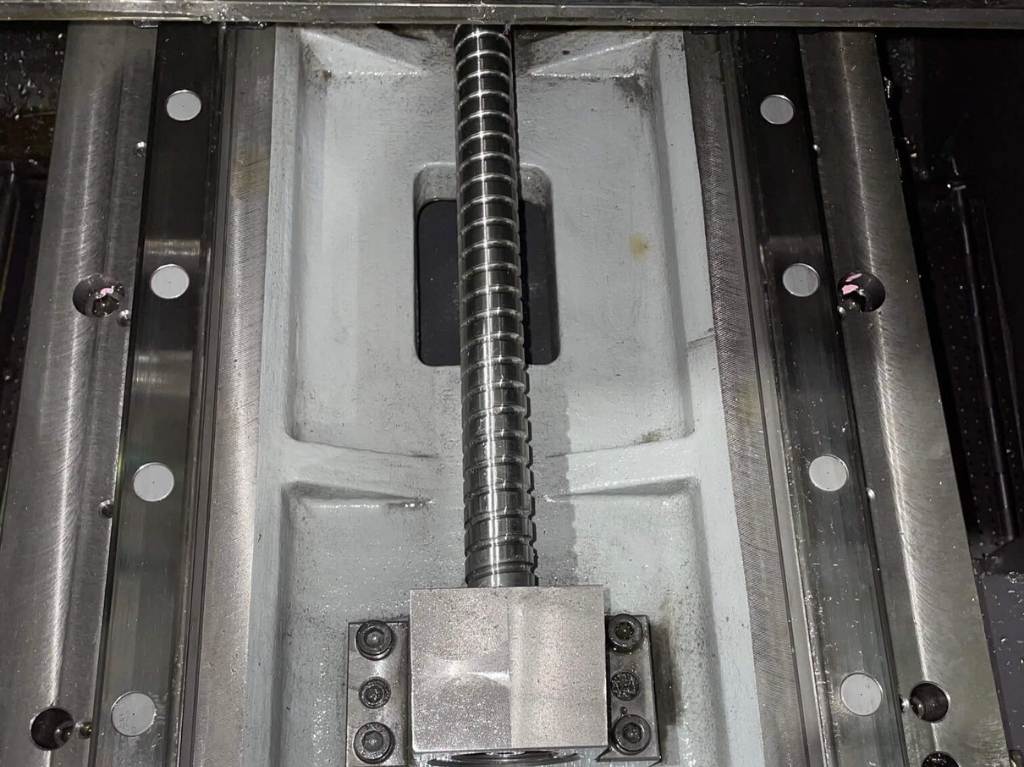

Motion Systems

- All wipers and belts are checked, and covers are pulled back to inspect the ways, guides, and ballscrews; areas are cleaned.

- Ball screws are checked for smooth and proper operation.

- All geometries and levels are checked.

- All machine functions are checked for correct operation and alignment.

Electrical & Safety

- All critical voltages are checked, and electrical connections are verified to be tight.

- All safety interlocks are checked, and any other safety issues are reported.

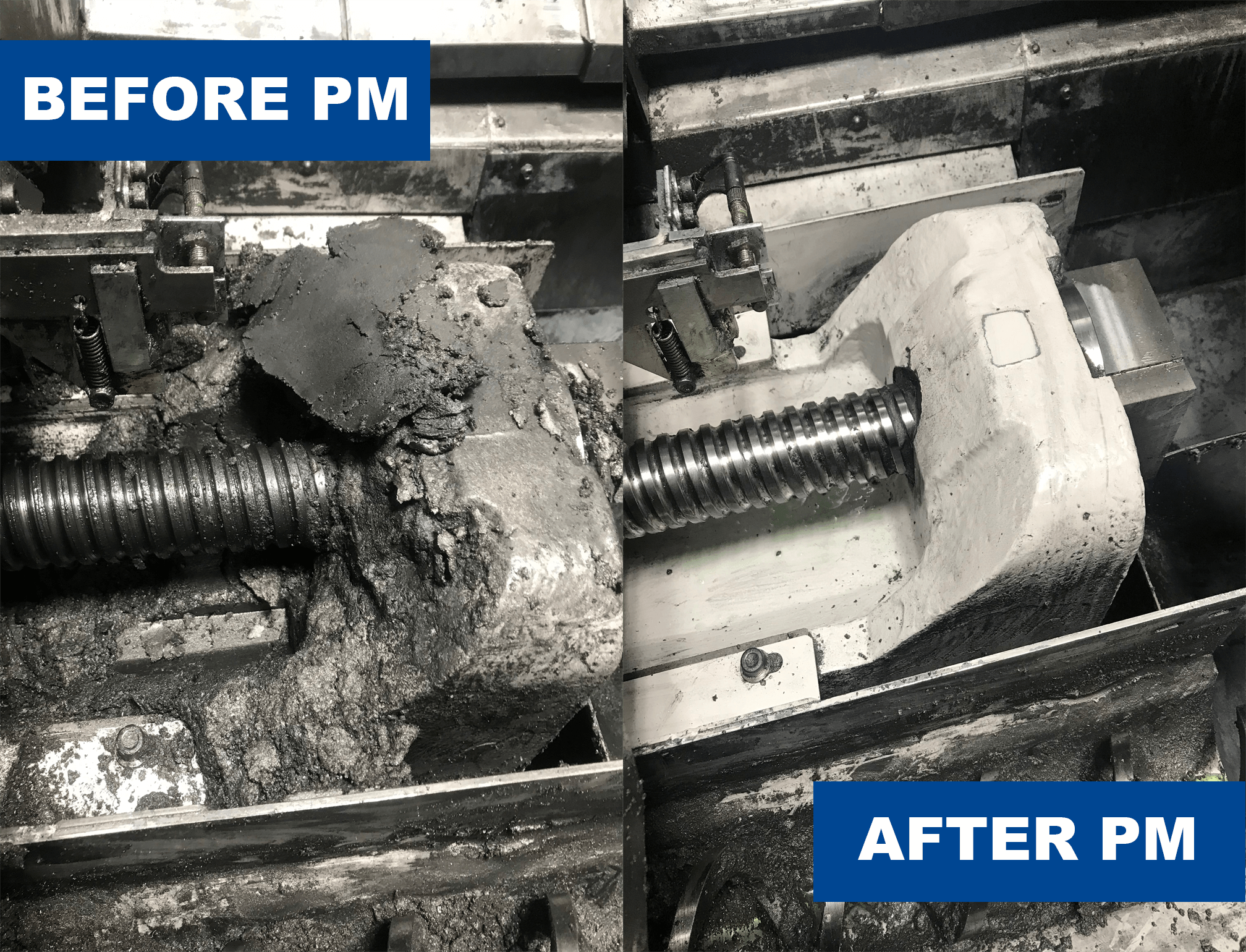

See the Difference Preventative Maintenance Makes

Linear Guide

Ballscrew

Motor Fan

Contact Us

Please contact us for additional information regarding these services.

Per applicable machine manuals, customers are responsible for complying with daily, weekly, one month, 3 month, and six month to a year Inspection, Maintenance and Adjustment requirements. Many Inspection, Maintenance and Machine adjustment requirements don’t align with yearly PM intervals.

TEL 860-687-3300

FAX 860-687-3476

FOLLOW US