Okuma Robot Loader - Machining Center

The ORL-MC is a compact, easy-to-use mill tending system.

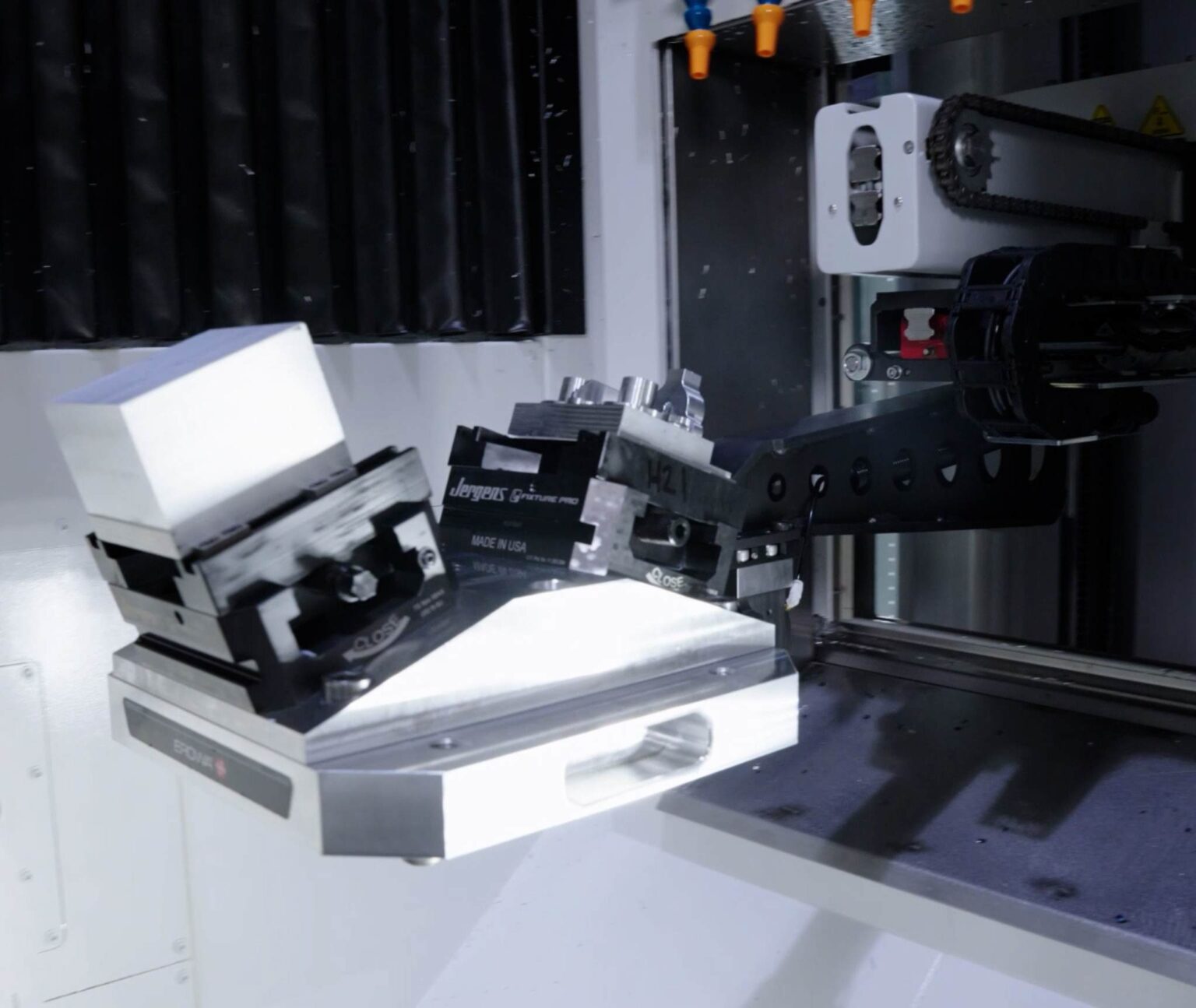

The ORL-MC utilizes a work holding system called MULTIGRIP™. This system is based upon the vise jaws also serving as the robot gripper fingers. This allows the robot to handle any geometry of part that can be held in your machined jaws.

The MULTIGRIP™ consists of top jaws, base jaws, and a Schunk pneumatic vise.

The robot will retrieve the associated jaws from the dedicated vise jaw rack for the specific part it will be handling. This flexible work holding and job control capability makes the ORL-MC a great solution for high-mix, low volume work.

Machine Pairings:

GENOS M460-VE, GENOS M460V-5AX, GENOS M560-V, GENOS M560V-5AX, MB-46V II, MB-56V

25lbs

9"

288 parts (size dependent)

- Diameter: 7.5"

- Width, Rectangular: 8.5"

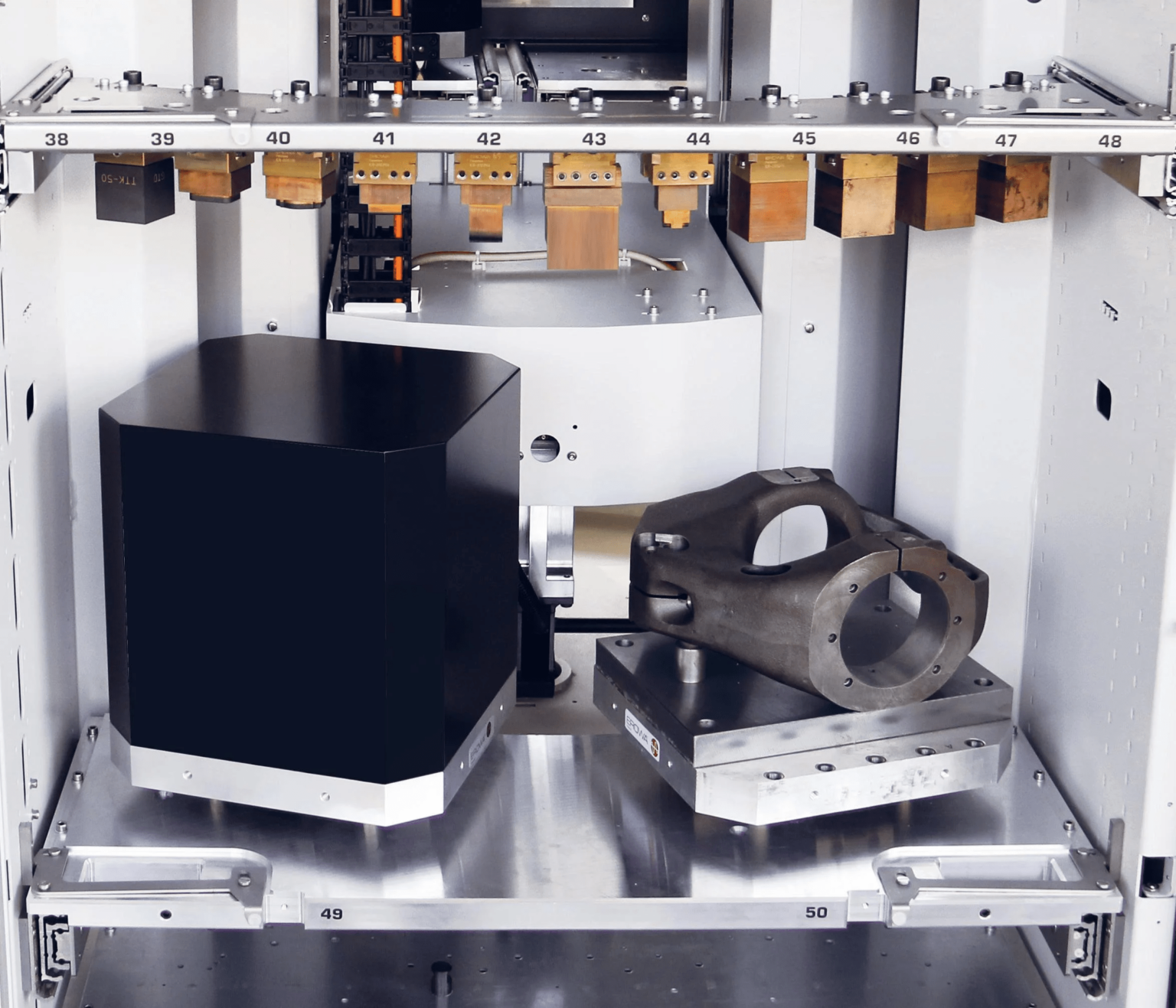

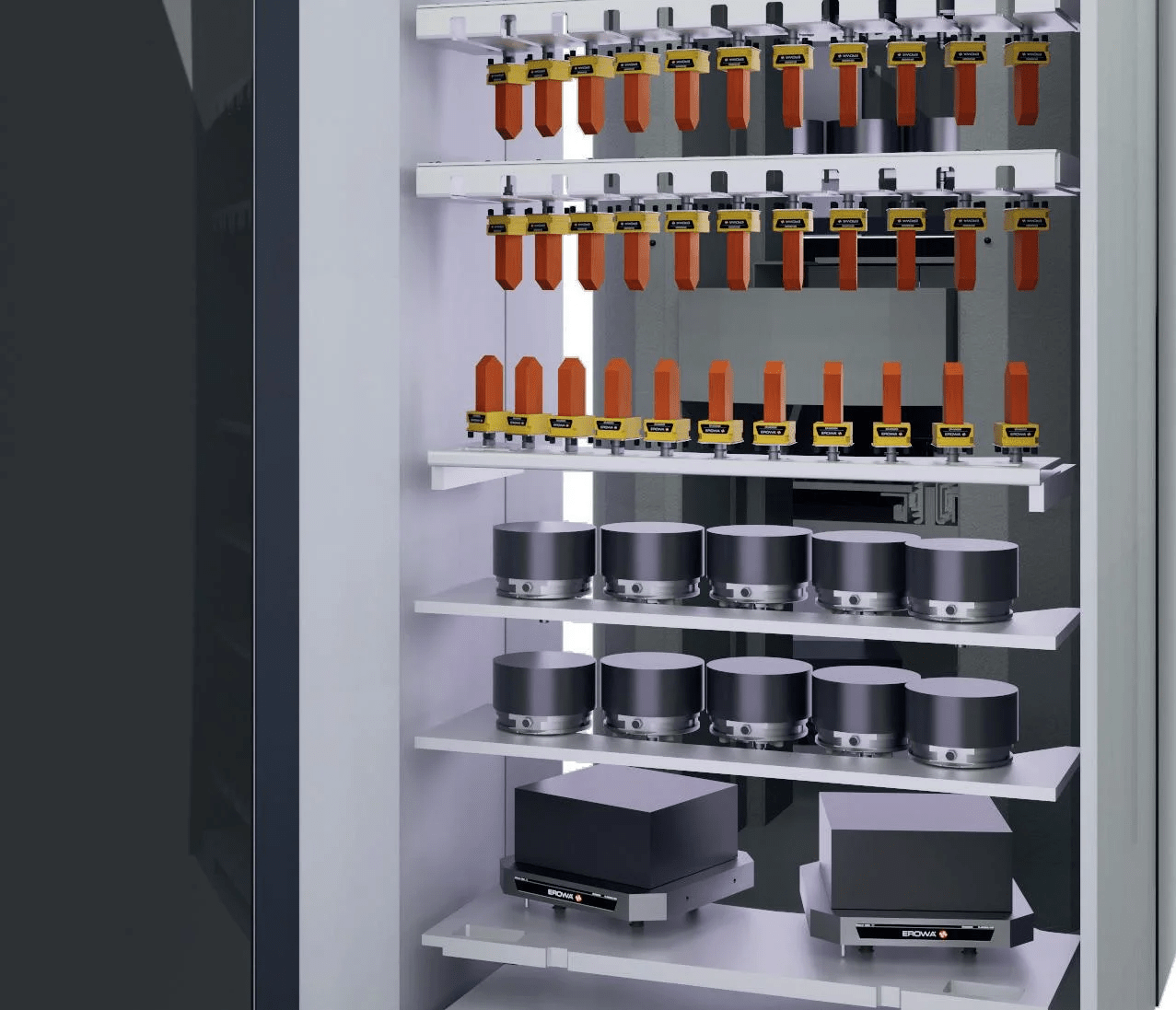

EROWA Robot Compact 80

The EROWA Robot Compact 80 provides the optimal ratio between a large number of magazine positions and a small amount of floor space.

The tall and lean design of the Robot Compact 80 is suitable for optimal floor space use in the workshop. With a transfer weight capacity of up to 176.37 lbs, it can serve one or two machine tools.

Ready to Automate Your Operations?

Morris Automation can help you find the right setup to streamline your workflow. Fill out the form and our team will be in touch shortly.

TEL 860-687-3300

FAX 860-687-3476

FOLLOW US