Key Pain Points We Solve

- Micron-level precision & fine detail

- Stringent regulatory compliance

- Challenging materials

- Surface finish and burr control

- Short-run, high-mix production

- Traceability & part serialization

- Cleanroom or sterile manufacturing environments

Common medical parts we support

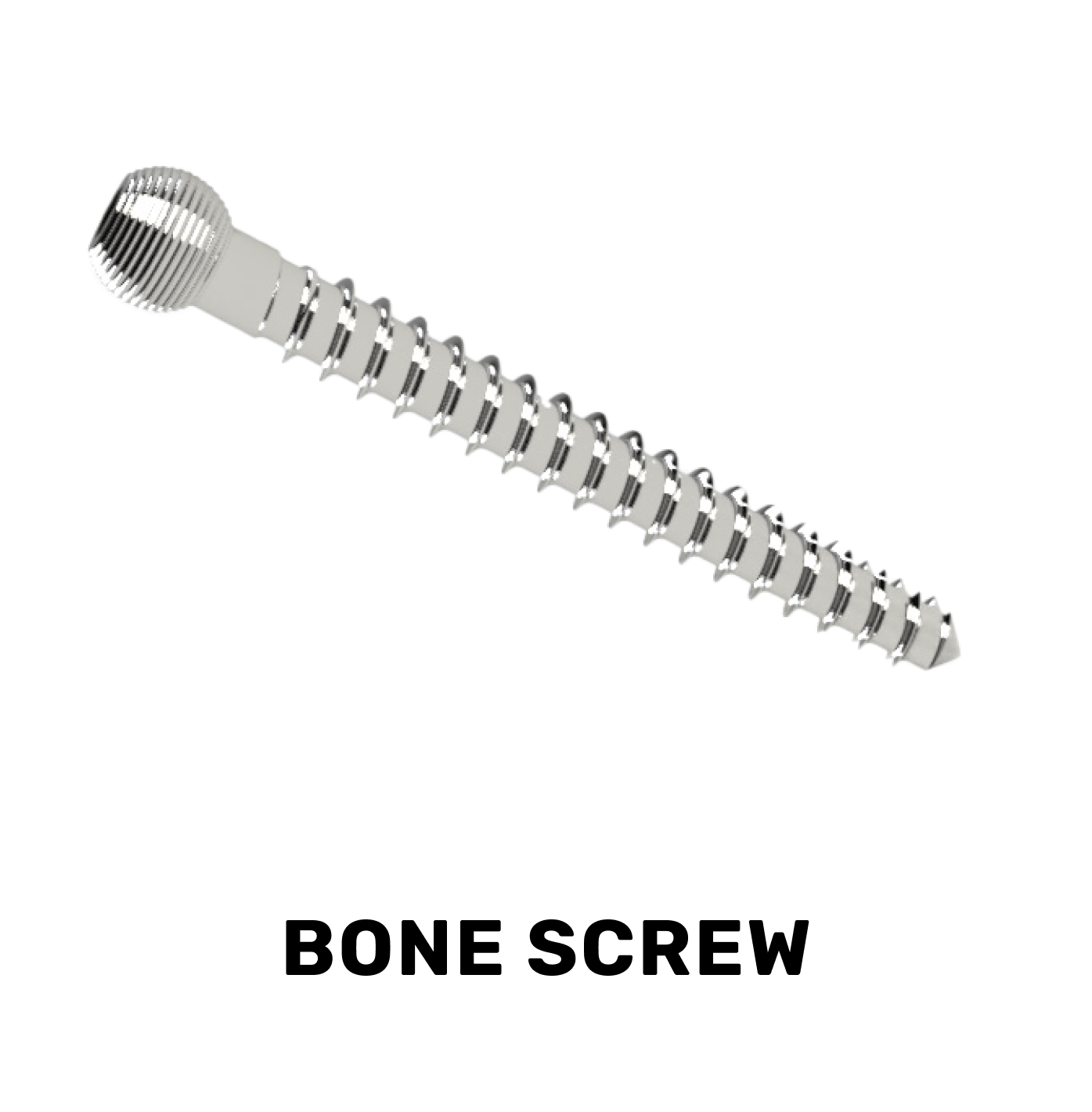

- Orthopedic bone screws and plates

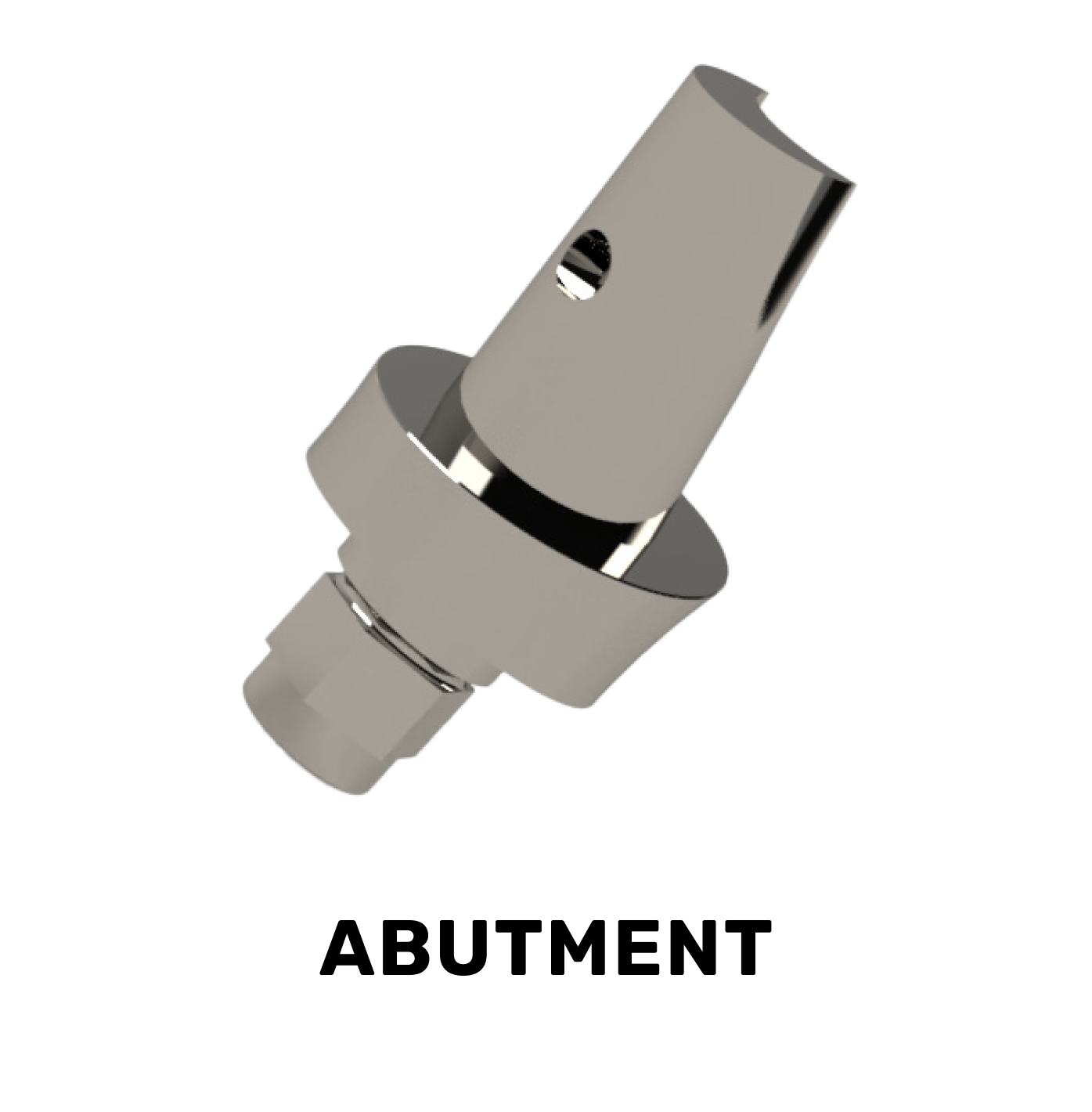

- Dental abutments and handpiece components

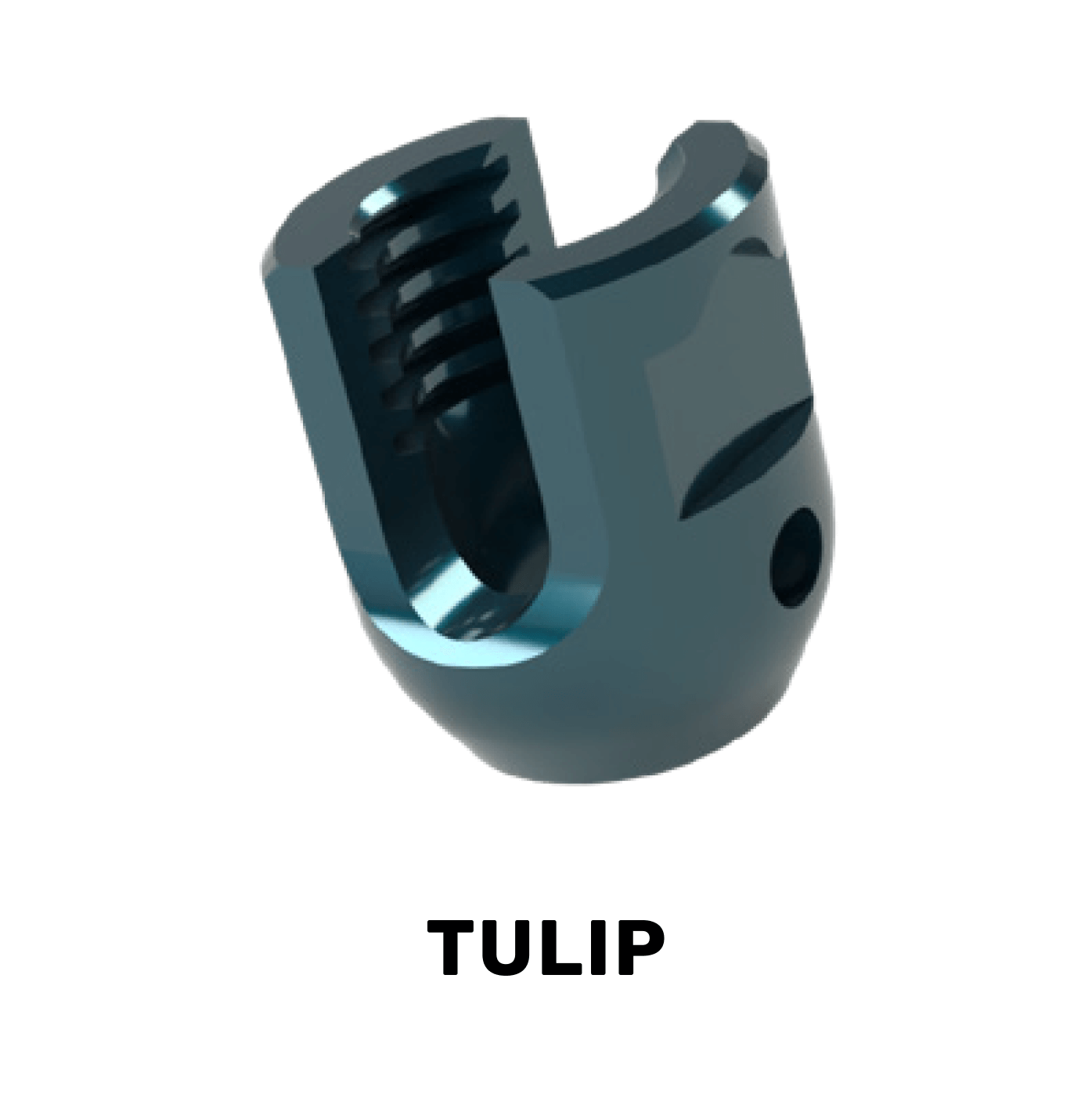

- Maxillofacial implants and spinal cages

- Hip/knee joints and surgical tools

- Biopsy cups and cardiovascular stents

Processes and capabilities

- 5‑axis, Swiss, and micromachining

- Thread whirling and drill/tap

- Laser/part marking and non‑contact inspection

- Integrated measurement and traceability

Medical Machined Parts

How We Help Medical Shops Succeed

Protect Uptime

Preventive maintenance, emergency service, and parts to minimize downtime.

Improve Quality

Application support for burr control, surface finish, and stable micron‑level tolerances.

Upskill Your Team

Operator, programmer, and maintenance training tailored to your workloads.

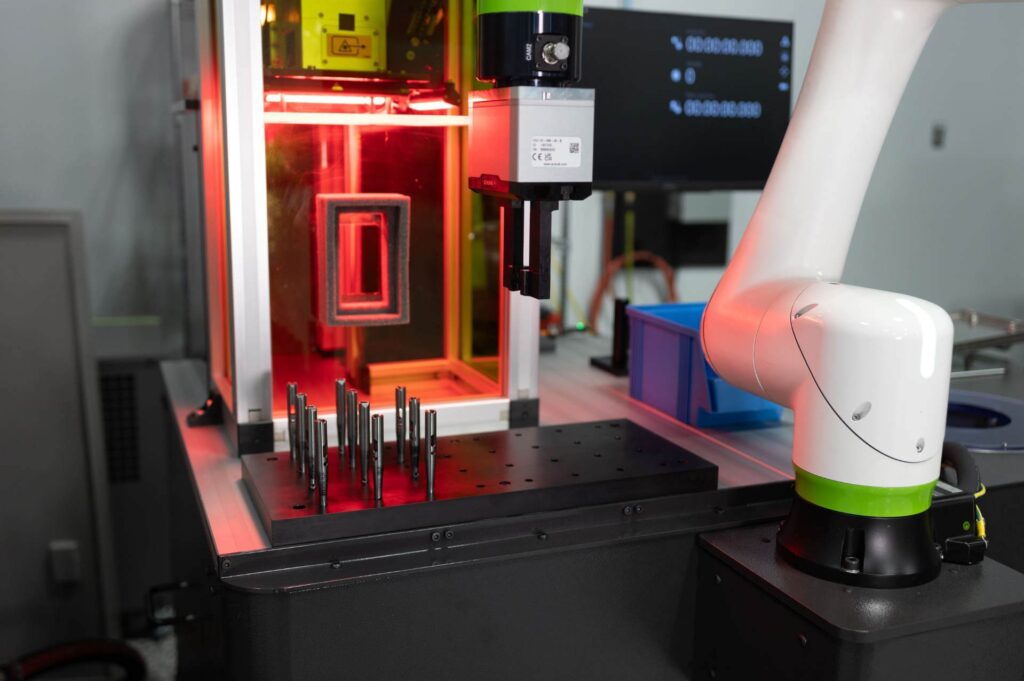

Automation that supports compliance

Morris Automation helps medical manufacturers boost quality and throughput while maintaining the process control demanded by regulated environments. Our solutions are designed for delicate, small-scale components such as automating handling, inspection, and part tracking.

- Cobot tending and micro‑part handling

- Flexible pallets and pre‑kitted cells

- In‑process measurement and SPC

- Serialization and UDI workflows

Financing built for manufacturers

Machinery Finance Resources (MFR) specializes in direct capital equipment financing. They can help you evaluate various methods of financing your equipment investment, ensuring you get the best possible terms and conditions.

- Simple, fast, convenient process

- Fast track application, good for up to $750,000. No financial statements

- Flexible payment options & terms

- Credit decision within hours

- 100% financing options

Customer Success Stories

Start Your Medical Project

Tell us about your operation, pain points, and production goals. We’ll share how our service, training, and automation expertise can help you move faster and stay ahead.

- No‑obligation consultation

- Tailored process recommendations

- Local service and support network

TEL 860-687-3300

FAX 860-687-3476

FOLLOW US