Key Pain Points We Solve

- Tight tolerances and high precision

- Complex part geometries

- Difficult-to-machine materials

- Traceability and compliance

- Long cycle times and low batch volumes

- Labor and skill shortage

- High scrap costs

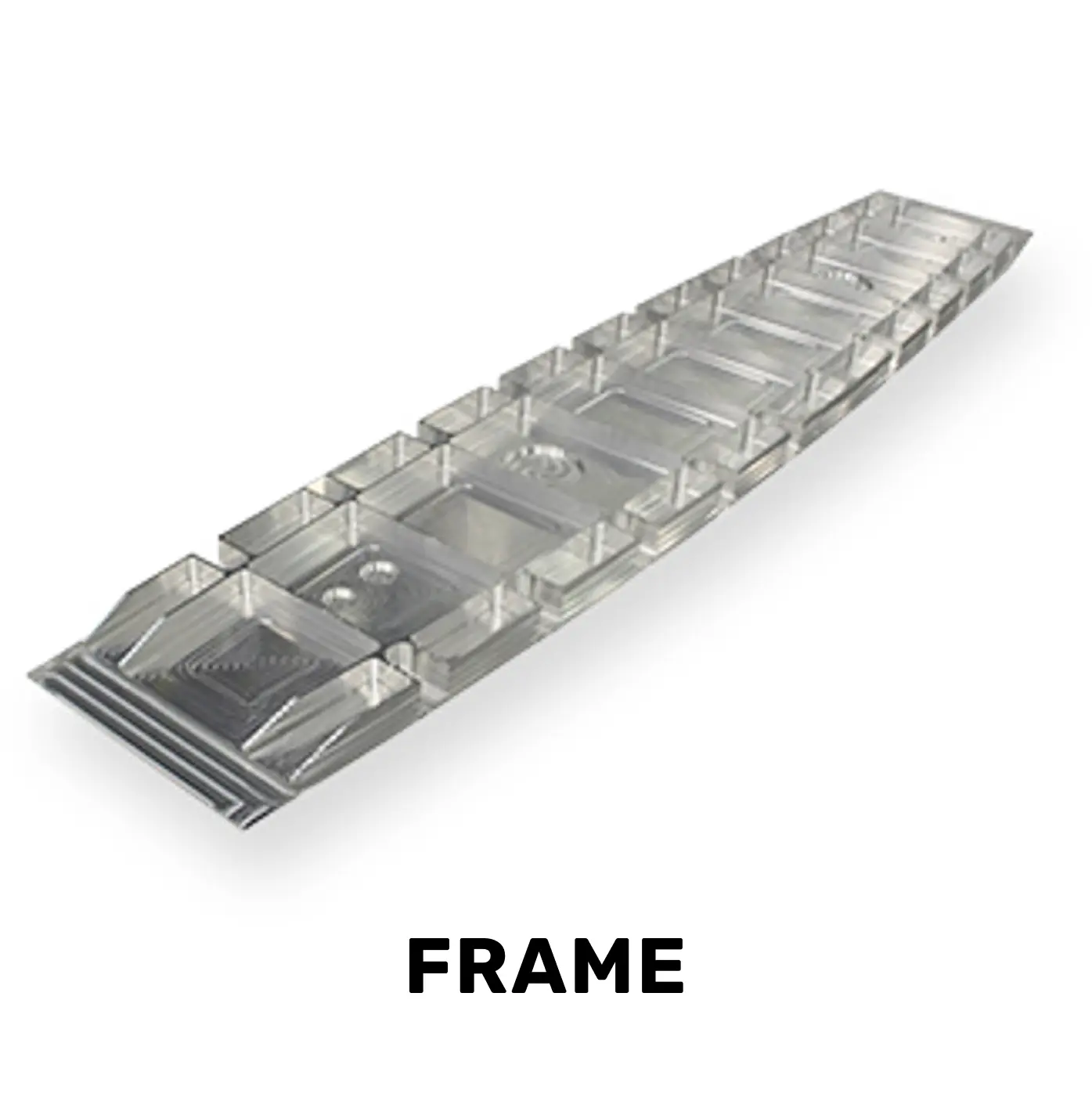

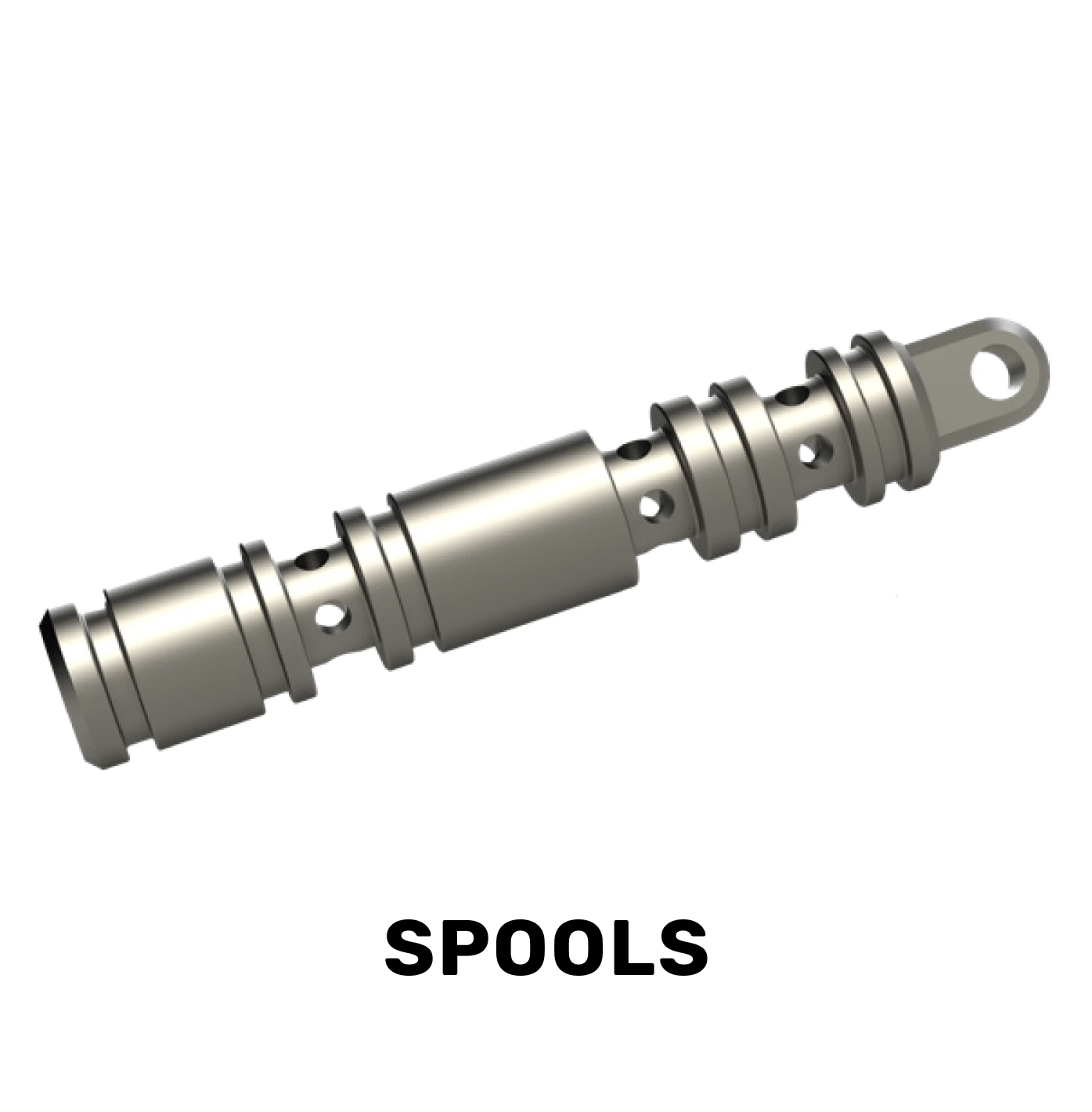

Common aerospace parts we support

- Turbine blades, vanes, airfoils, blisks and impellers

- Rotors, root forms, fan blades (solid and hollow)

- Frames, spars, beams, cabin panels

- Landing gear components and hubs

Processes and capabilities

- 5‑axis machining, horizontal/vertical milling and turning

- Grinding

- Robotic polishing, buffing, grinding

- Boring (horizontal and vertical)

- Part marking and quality control

Materials and compliance

- Titanium, Inconel, nickel alloys

- In‑line inspection and serialization

- Traceability for NADCAP/FAA audits

Aerospace Machined Parts

How We Help Aerospace Shops Succeed

Keep production moving

Preventive maintenance, emergency service, and parts to minimize downtime.

Hit tolerance and finish

Application support for cycle time, tooling, and quality improvements.

Upskill your team

Operator/programmer training aligned to aerospace workflows and audits.

Automation That Keeps You Flying Forward

Morris Automation helps aerospace manufacturers enhance consistency, efficiency, and traceability for small-batch development parts or full-rate production. We design automation solutions that improve spindle utilization and repeatability while maintaining compliance with aerospace quality and documentation standards.

- Collaborative tending and pallet systems

- Pre-kitted cells with probing and tool presetting

- In-process inspection, part marking, and data capture

Financing built for manufacturers

Machinery Finance Resources (MFR) specializes in direct capital equipment financing. They can help you evaluate various methods of financing your equipment investment, ensuring you get the best possible terms and conditions.

- Simple, fast, convenient process

- Fast track application, good for up to $750,000. No financial statements

- Flexible payment options & terms

- Credit decision within hours

- 100% financing options

Customer Success Stories

How Precision Machine of Savannah Keeps Production Moving Forward

First-Class Innovation in Aerospace Manufacturing: Kencoa Aersospace

Start Your Aerospace Project

Tell us about your operation, pain points, and production goals. We’ll share how our service, training, and automation expertise can help you move faster and stay ahead.

- No‑obligation consultation

- Tailored process recommendations

- Local service and support network

TEL 860-687-3300

FAX 860-687-3476

FOLLOW US