Custom Machine Automation Systems

At Morris, we offer more than top-of-the-line machine tools, we provide automation solutions designed to enhance your equipment’s performance. Our portfolio includes a full range of standard pre-engineered systems as well as fully custom-engineered solutions. If your automation needs align with our standard specifications, our pre-built robot cells deliver cost savings and faster delivery.

For more specialized requirements, Morris can develop a tailored solution to meet your exact needs. Whether standard or custom, our automation offerings are built to maximize efficiency and productivity.

Custom Machine Tool Automation Systems

Automate Smarter. Machine Better

Every automation cell we build is designed with your unique goals in mind. These examples show just how flexible our approach is:

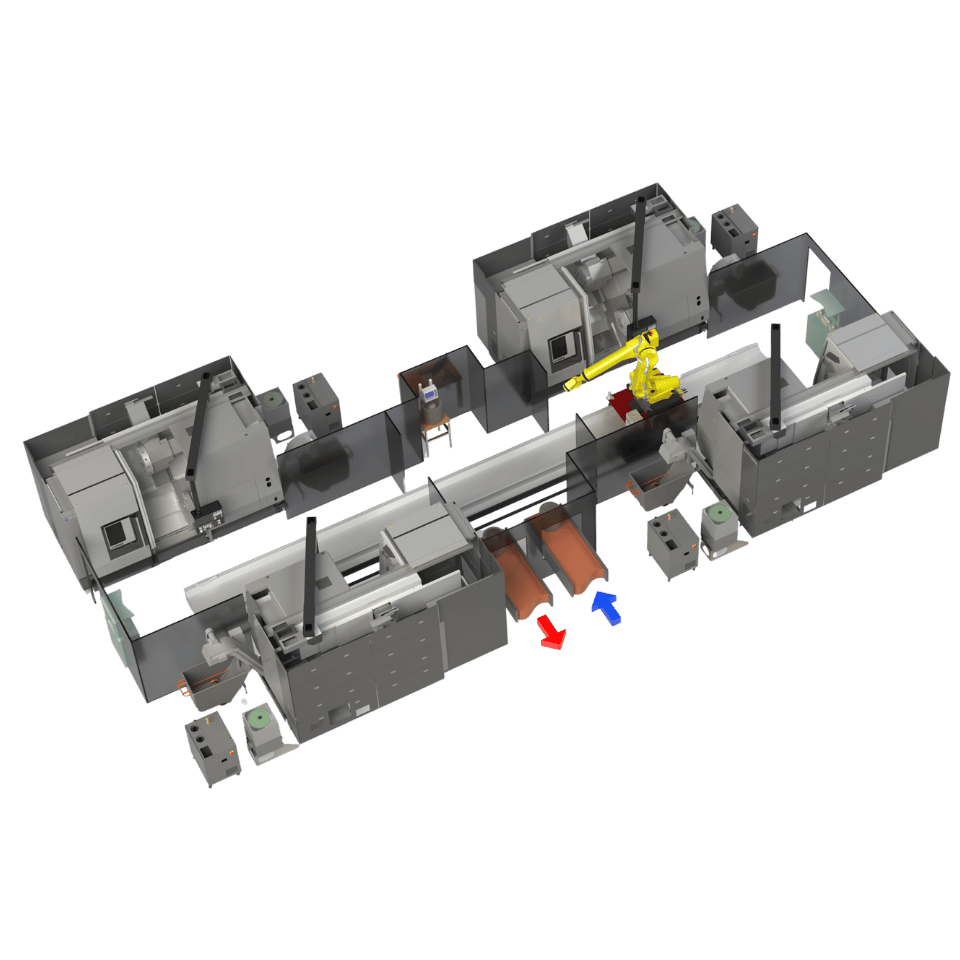

Four Machine RTU Automation Cell

This installation automates a four-machine setup using a rail-mounted robot for seamless part transfer. With conveyor-fed loading/unloading and built-in inspection, the system delivers consistent throughput and lights-out potential.

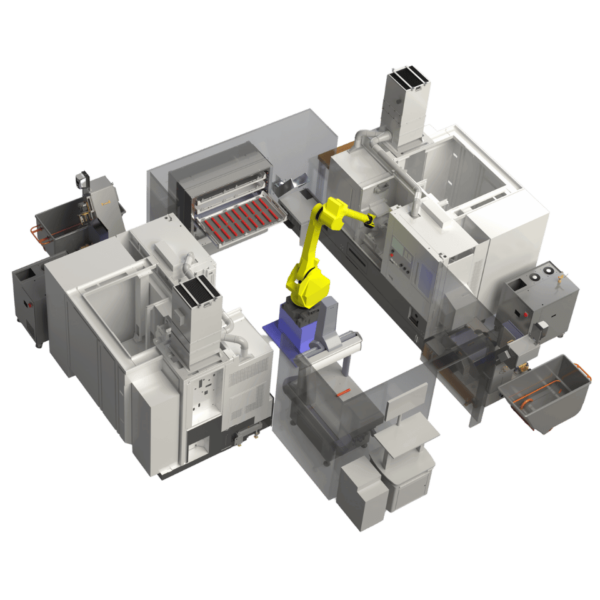

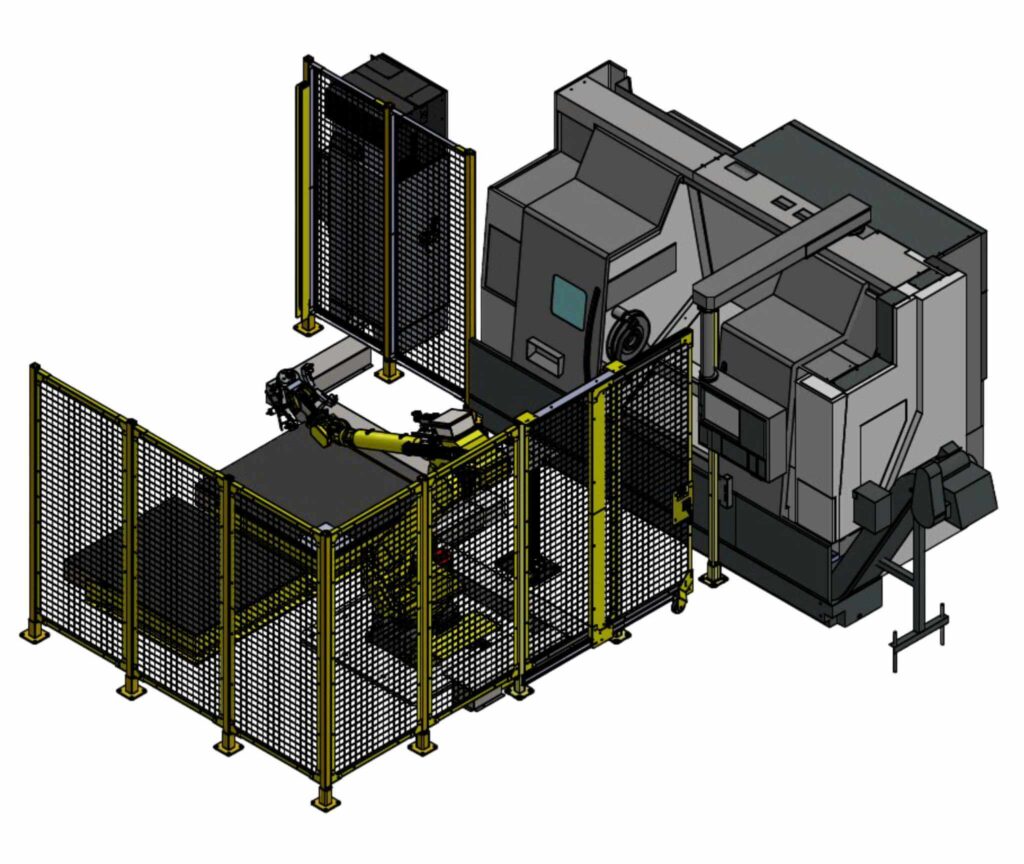

Dual Lathe CMM Inspection Cell

This setup automates two lathes with a floor-mounted robot, drawer-style part handling, and CMM inspection—all designed to boost consistency and reduce manual labor.

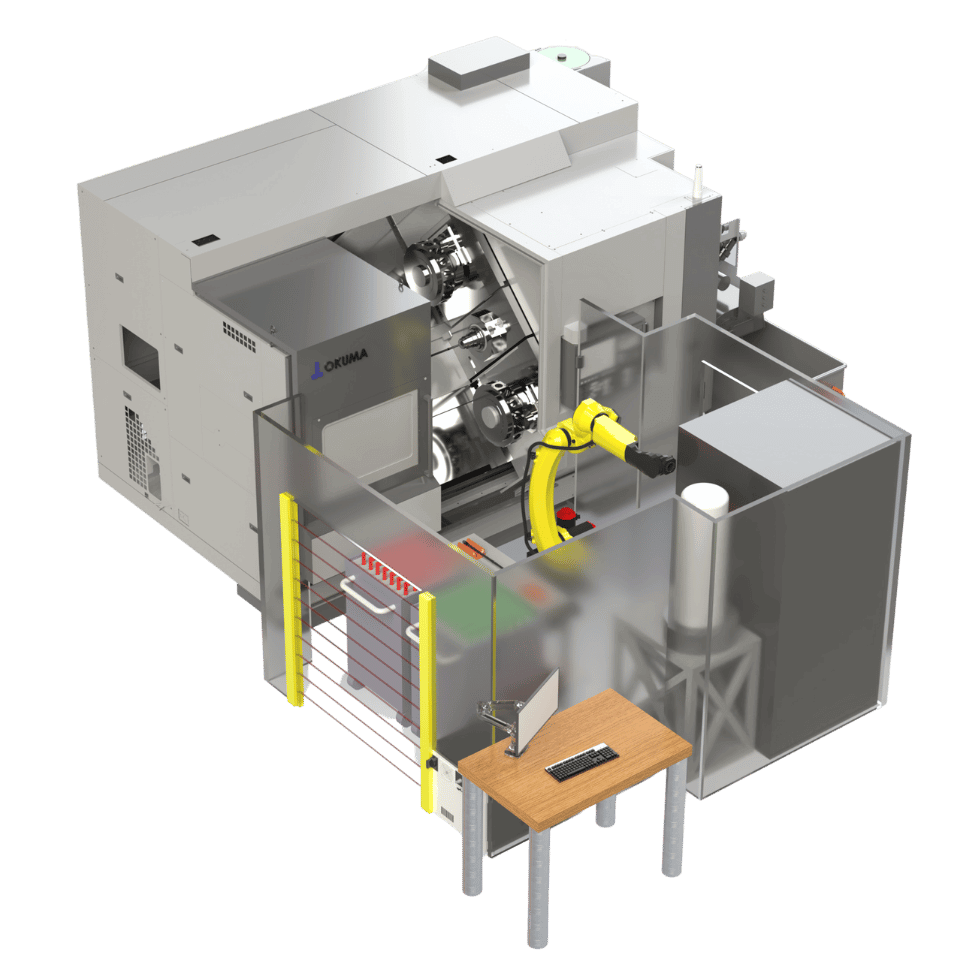

Lathe Tending Inspection Cell

A floor-mounted robot handles part tending for a lathe, with a cart system for loading/unloading, plus air blow and inspection to maintain part quality and process consistency.

Automation Within Reach Plus Series

The Plus Series from Automation Within Reach offers single or dual-machine operation with Pallet, Drawer, or Conveyor cell options. Custom end-of-arm tooling (EOAT) ensures it fits your specific application needs.

AWR - CC+ – Conveyor Automation Cell

AWR’s Conveyor Cell streamlines machining automation, ideal for boosting efficiency in low-mix, high-volume production.

This comprehensive solution centers around a high-performance Fanuc

M-710iC six-axis industrial robot, providing the dexterity and precision needed for complex part handling.

Product Details

- One or two machine configurations available

- Fanuc M-710iC six axis industrial robot

- End of arm tooling (EoAT) with dual grippers

- Single part handling: 55 lbs part capacity

- Dual part handling: 28 lbs part capacity

- Powered inbound/outbound flat belt conveyors

- Engineering & tooling for 1 part number included within the

base price - Machine side options for access and communication with

automation are required

Options Available

- 2nd machine (Lathe or VMC)

- Part turnover station (OP10/OP20 processing)

- Ambient air blow-off station

- Part audit drawer

- Post process gage station

- Part marking station (dot peen or laser)

AWR - DC+ – Drawer Automation Cell

This automated solution is ideal for manufacturers seeking to

streamline operations, particularly those in low-mix, high-volume

environments.

By automating part handling, the DC+ significantly increases throughput, reduces labor costs, and improves your overall efficiency.

Product Details

- One or two machine configurations available

- Fanuc M-710iC six axis industrial robot

- End of arm tooling (EoAT) with dual grippers

- Single part handling: 55 lbs part capacity

- Dual part handling: 28 lbs part capacity

- Heavy duty 4 drawer unit for inbound/outbound part handling

- Engineering & tooling for 1 part number included within the

base price - Machine side options for access and communication with

automation are required

Options Available

- 2nd machine (Lathe or VMC)

- Part turnover station (OP10/OP20 processing)

- Ambient air blow-off station

- Part audit drawer

- Post process gage station

- Part marking station (dot peen or laser)

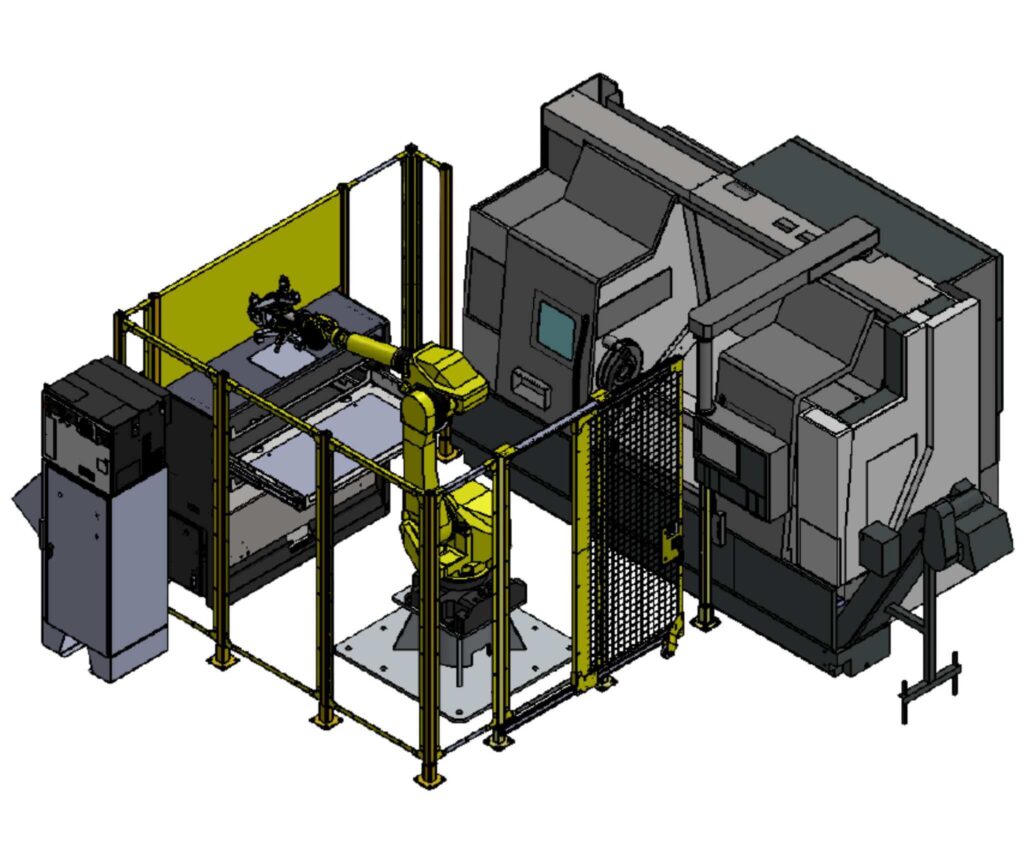

AWR - PC+ – Pallet Automation Cell

The Flexible Pallet Cell is the perfect solution for high-volume and

low-mix manufacturing environments.

The PC+ is a comprehensive system that incorporates a high performance Fanuc M-710iC six-axis industrial robot, providing the dexterity and precision needed for complex part handling.

Product Details

- One or two machine configurations available

- Fanuc M-710iC six axis industrial robot

- End of arm tooling (EoAT) with dual grippers

- Single part handling: 55 lbs part capacity

- Dual part handling: 28 lbs part capacity

- Single layer 48” x 48” Pallets - 2 included

- Engineering & tooling for 1 part number included within the

base price - Machine side options for access and communication with

automation are required

Options Available

- 2nd machine (Lathe or VMC)

- Part turnover station (OP10/OP20 processing)

- Ambient air blow-off station

- Part audit drawer

- Post process gage station

- Part marking station (dot peen or laser)

Ready to Automate Your Operations?

Morris Automation can help you find the right setup to streamline your workflow. Fill out the form and our team will be in touch shortly.

TEL 860-687-3300

FAX 860-687-3476

FOLLOW US

© 2026 Morris. All Rights Reserved.

Privacy Policy | Site Map