Overview

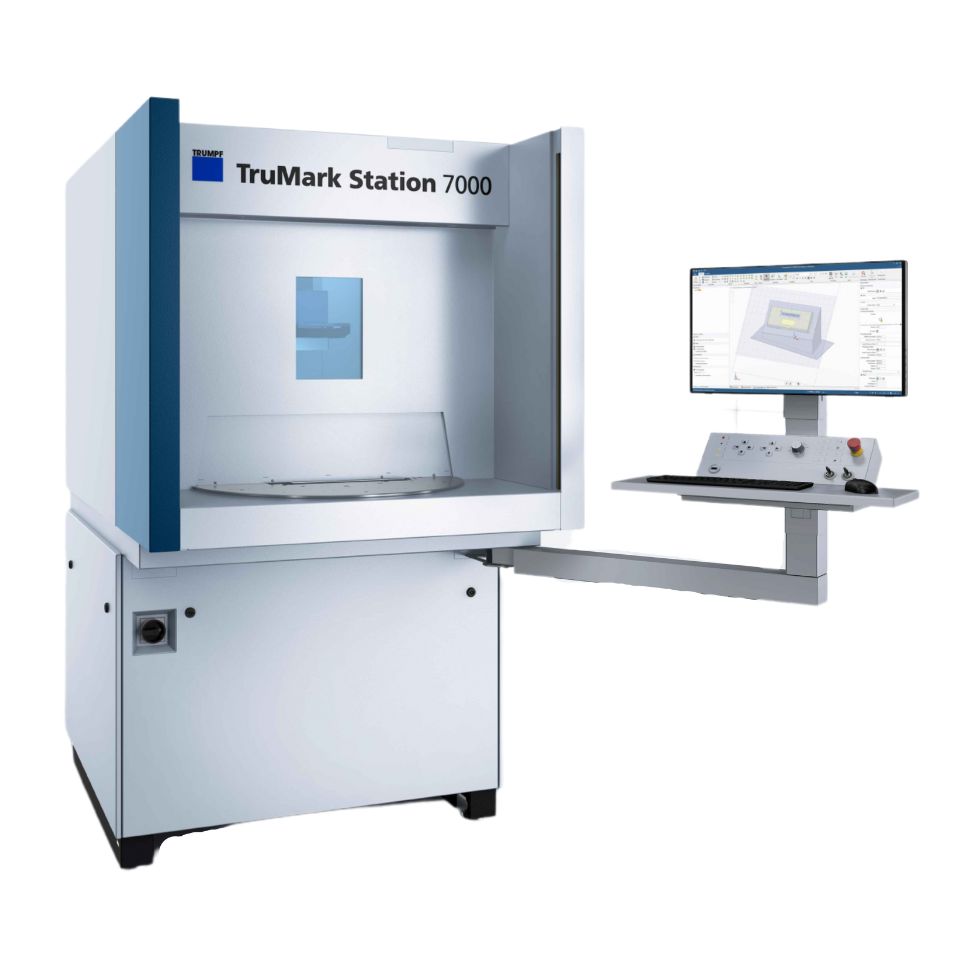

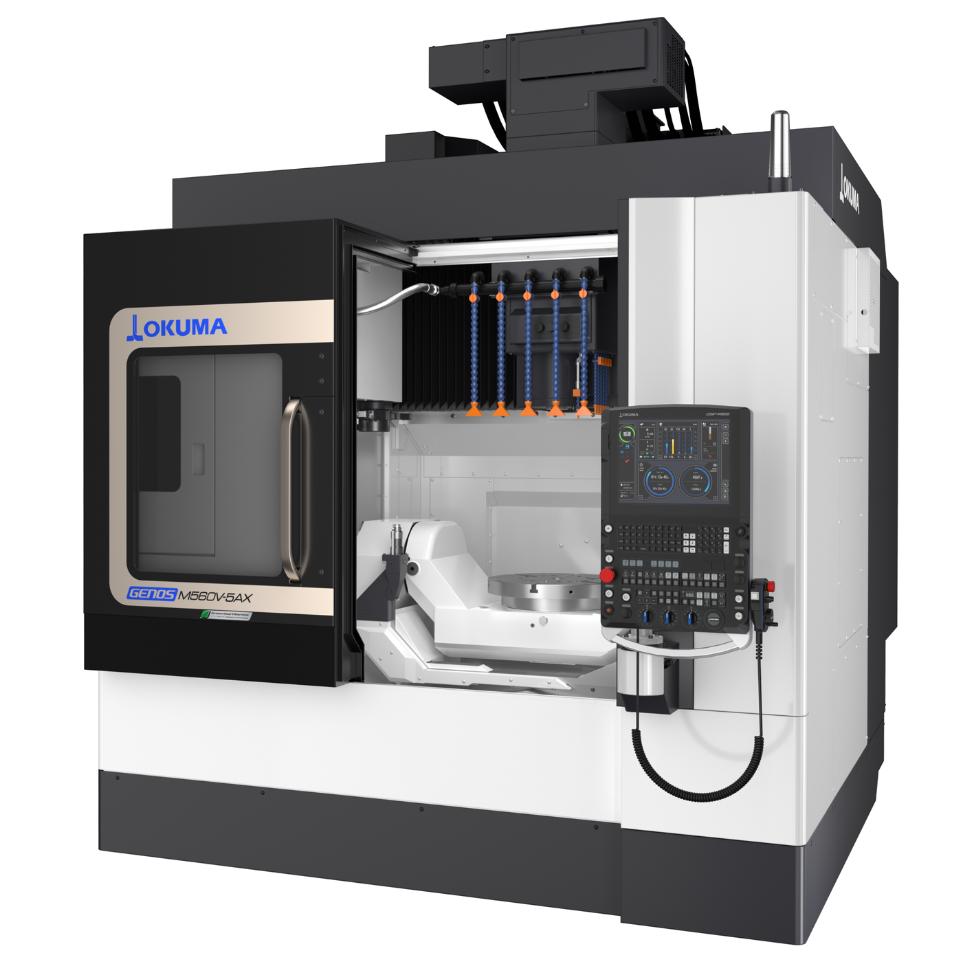

Morris Great Lakes provides CNC machinery and related engineering and support services to manufacturers of precision machined parts including horizontal and vertical lathes, laser marking systems, and 5-axis machines, to name a few.

Our mission is to help our customers improve productivity and profitability. From large turbine blisks to small medical parts, from firearm and electronic components to custom parts, our application engineers possess the process expertise to bring virtually any part from prototype to the production floor in the shortest time possible. Large OEMs, tier one suppliers, and independent job shops rely on our products and services for high production work, custom applications, and everything in between.

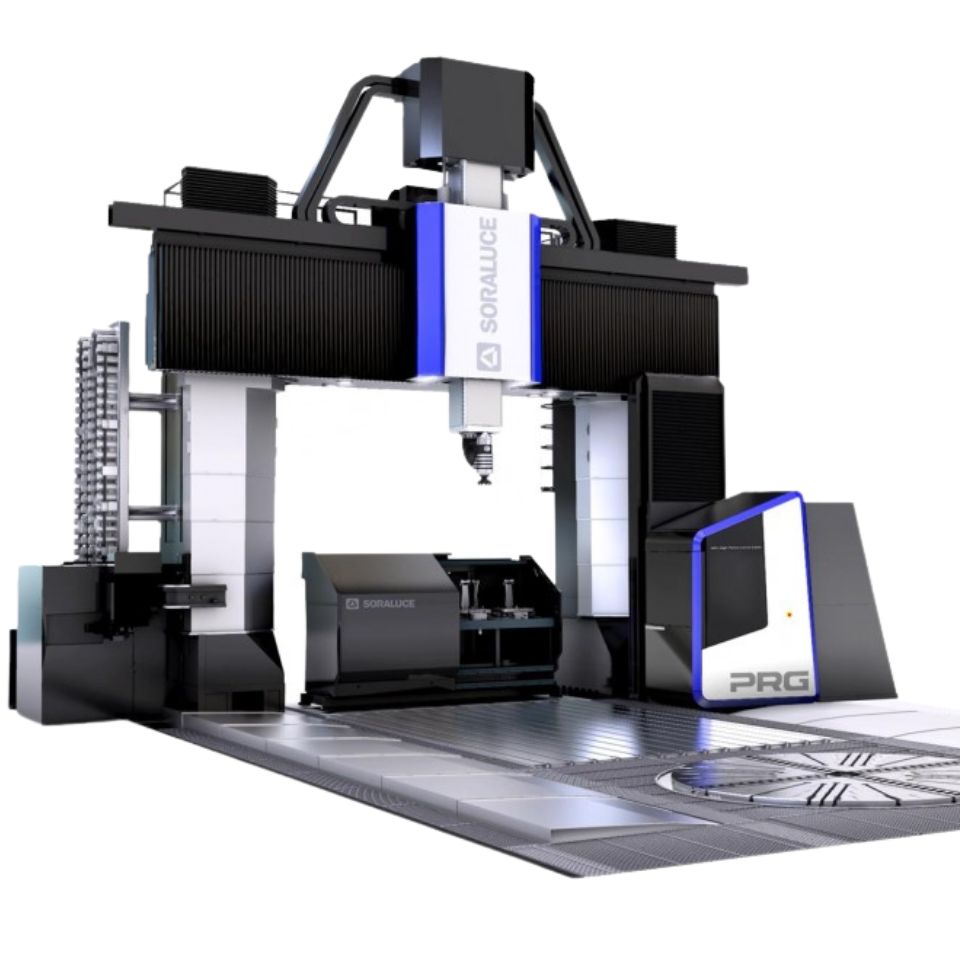

4+2 Machining Cuts Cycle Times From Days to Minutes

Upgrading the right piece of equipment can make a major difference in everyday production. Highland Manufacturing saw this when they purchased the Soraluce TAD25 milling and boring machine. It helped them combine multiple steps into one setup, cut cycle times from days to minutes, and handle large diameter aerospace and defense parts with better accuracy. The improvement also opened the door for expanded opportunities that contributed to a 10% sales increase.

Click below to read the full story and see how updating older machines can improve output and capability!

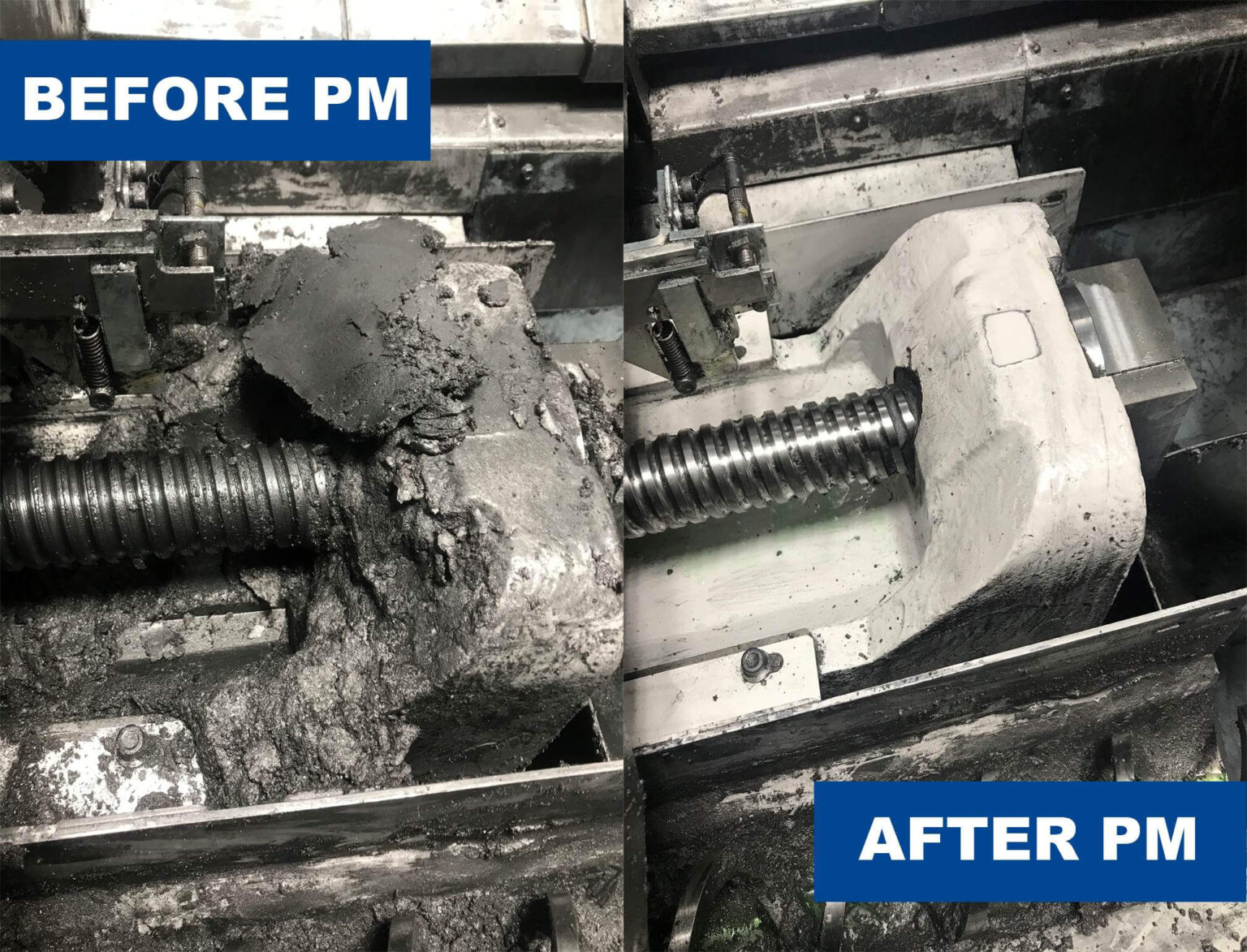

Preventative Maintenance Solutions

Our Preventative Maintenance support team is willing and able to help you get ahead of any problems or pain points that can occur and cause delays in your machine production time and functionality.

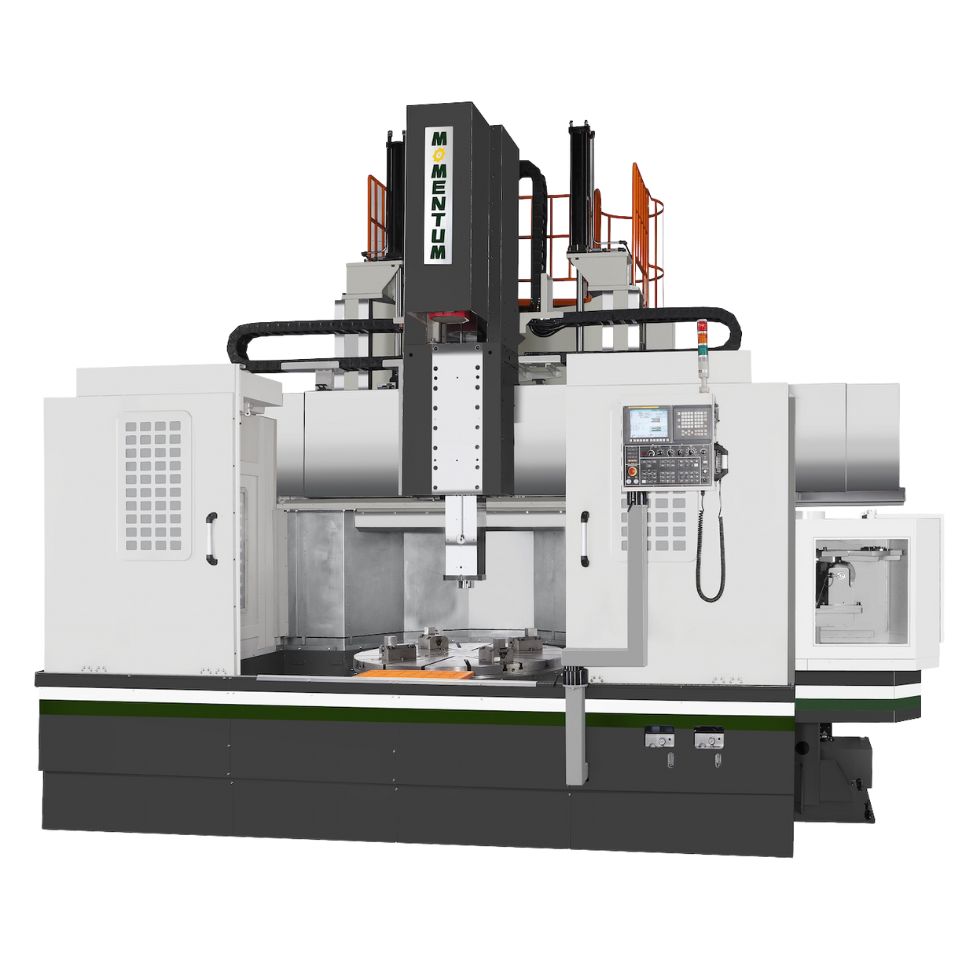

Machine Tool Lines Represented

Our strong relationships with our technology partners means that we can provide you with the best solutions to your manufacturing problems.

Select a builder for service, parts, engineering, or sales requests: